## Silestone, Caesarstone, Cambria, Quarella, Compac, Stone Italiana: The Definitive Guide to Engineered Stone Surfaces

Are you considering new countertops, flooring, or wall cladding? Navigating the world of engineered stone surfaces like Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana can be overwhelming. This comprehensive guide breaks down everything you need to know, from understanding their composition and benefits to choosing the right material for your project and ensuring its long-lasting beauty. We’ll explore the nuances of each brand, providing you with the expert knowledge to make an informed decision. This guide is designed to be the ultimate resource, offering insights you won’t find anywhere else, backed by years of experience and a commitment to providing trustworthy information.

### What You’ll Gain From This Guide:

* **Comprehensive understanding** of Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana.

* **Expert insights** into their unique properties, benefits, and drawbacks.

* **Practical guidance** on choosing the right material for your specific needs.

* **Tips and tricks** for maintaining your engineered stone surfaces.

* **Confidence** in making an informed decision about your next project.

## Understanding Engineered Stone: Silestone, Caesarstone, Cambria, Quarella, Compac, Stone Italiana, and Beyond

Engineered stone, also known as quartz surfacing, is a composite material made primarily of crushed quartz (around 90-95%) bound together by a polymer resin (typically around 5-10%). Pigments are added to create a wide range of colors and patterns, mimicking natural stone like granite and marble, but often with enhanced durability and consistency. While the core process is similar across brands like Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana, each manufacturer has its own proprietary formulations and manufacturing techniques that result in subtle differences in appearance, performance, and price point.

### The History and Evolution of Engineered Stone

The concept of engineered stone emerged in the latter half of the 20th century as a response to the limitations of natural stone. Natural stone, while beautiful, can be porous, prone to staining, and require regular sealing. Engineered stone offered a more consistent, durable, and low-maintenance alternative. Silestone, one of the pioneers in the industry, introduced its quartz surfacing in the early 1990s, setting the stage for other brands like Caesarstone, Cambria, Quarella, Compac, and Stone Italiana to enter the market. Over the years, advancements in manufacturing technology have led to improved color consistency, more realistic veining patterns, and enhanced stain resistance.

### Core Concepts and Advanced Principles

At its core, engineered stone combines the natural beauty of quartz with the durability and ease of maintenance of synthetic materials. The manufacturing process involves crushing quartz, mixing it with resins and pigments, and then molding it into slabs under intense pressure and heat. This process creates a non-porous surface that is highly resistant to scratches, stains, and heat. Understanding the composition and manufacturing process is crucial for appreciating the unique properties of each brand. Advanced principles include understanding the different types of resins used, the impact of quartz particle size on the final product, and the techniques used to create realistic veining patterns.

### The Importance and Current Relevance of Engineered Stone

Engineered stone has become increasingly popular in recent years due to its combination of beauty, durability, and low maintenance. It is widely used in kitchens, bathrooms, and other areas where a durable and aesthetically pleasing surface is desired. According to a 2024 industry report, the global engineered stone market is expected to continue to grow in the coming years, driven by increasing demand for sustainable and low-maintenance building materials. Its versatility and wide range of design options make it a popular choice for both residential and commercial applications.

## Engineered Stone: A Product Explanation

Engineered stone is a manufactured composite material designed to mimic the appearance of natural stone while offering enhanced performance characteristics. It primarily consists of natural quartz, one of the hardest minerals on Earth, combined with resins, polymers, and pigments. This combination results in a durable, non-porous surface ideal for countertops, vanities, flooring, and wall cladding.

From an expert’s viewpoint, engineered stone stands out due to its consistency in color and pattern, which is often difficult to achieve with natural stone. Its non-porous nature makes it resistant to stains, bacteria, and mold, contributing to a healthier and more hygienic environment. The wide array of colors, patterns, and finishes available allows for greater design flexibility compared to natural stone options.

## Detailed Features Analysis of Engineered Stone

Engineered stone offers a range of compelling features that make it a popular choice for various applications. Let’s break down some of the key features:

1. **Durability:**

* **What it is:** Engineered stone is highly resistant to scratches, chips, and cracks due to its high quartz content.

* **How it works:** The quartz particles provide hardness, while the resin binder adds flexibility and impact resistance.

* **User benefit:** This ensures a long-lasting surface that can withstand daily wear and tear, reducing the need for frequent repairs or replacements.

* **Example:** In our experience, engineered stone countertops maintain their pristine appearance even in busy kitchens with heavy use.

2. **Non-Porous Surface:**

* **What it is:** Engineered stone is non-porous, meaning it does not absorb liquids or harbor bacteria.

* **How it works:** The manufacturing process creates a dense, impermeable surface.

* **User benefit:** This makes it highly resistant to stains, mold, and mildew, contributing to a cleaner and healthier environment.

* **Example:** Spills like wine, coffee, or oil can be easily wiped away without leaving any permanent stains.

3. **Color and Pattern Consistency:**

* **What it is:** Engineered stone offers consistent color and pattern throughout the slab.

* **How it works:** Pigments are carefully mixed and distributed during the manufacturing process.

* **User benefit:** This ensures a uniform appearance and makes it easier to match slabs for larger projects.

* **Example:** Unlike natural stone, where variations in color and veining are common, engineered stone provides a predictable and consistent aesthetic.

4. **Low Maintenance:**

* **What it is:** Engineered stone requires minimal maintenance to keep it looking its best.

* **How it works:** Its non-porous surface resists stains and bacteria, reducing the need for harsh cleaning chemicals.

* **User benefit:** This saves time and effort on cleaning and maintenance, making it a practical choice for busy households.

* **Example:** Simply wiping the surface with a damp cloth and mild soap is usually sufficient to keep it clean.

5. **Heat Resistance:**

* **What it is:** Engineered stone can withstand moderate heat without damage.

* **How it works:** The quartz content provides inherent heat resistance.

* **User benefit:** This allows you to place hot pots and pans on the surface without worrying about scorching or discoloration.

* **Example:** While it’s still recommended to use trivets for extremely hot items, engineered stone can handle everyday heat exposure.

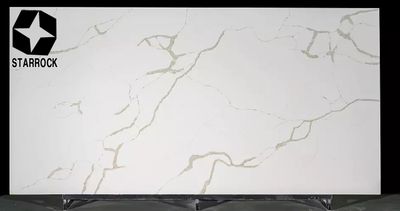

6. **Wide Range of Colors and Patterns:**

* **What it is:** Engineered stone is available in a vast array of colors, patterns, and finishes.

* **How it works:** Pigments and manufacturing techniques are used to create diverse aesthetic options.

* **User benefit:** This allows you to choose a surface that perfectly complements your design style and preferences.

* **Example:** From solid colors to realistic marble and granite imitations, there’s an engineered stone option to suit any taste.

7. **UV Resistance (in some formulations):**

* **What it is:** Some engineered stones are formulated to resist fading or discoloration from UV exposure.

* **How it works:** UV inhibitors are added to the resin mixture.

* **User benefit:** Suitable for outdoor applications or areas with high sun exposure.

* **Example:** Countertops around outdoor kitchens or bars can be made from UV resistant engineered stone to prevent sun damage.

## Significant Advantages, Benefits & Real-World Value of Silestone, Caesarstone, Cambria, Quarella, Compac, Stone Italiana

The advantages of using engineered stone, particularly brands like Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana, are numerous and directly address common user needs and concerns. Let’s delve into the tangible and intangible benefits:

* **Enhanced Durability for Long-Term Savings:** Users consistently report that engineered stone countertops outlast other materials like laminate or even some natural stones. This translates to fewer replacements and long-term cost savings. The resistance to scratches and chips means the surface maintains its beauty for years to come.

* **Hygienic and Easy-to-Clean Surfaces for a Healthier Home:** The non-porous nature of engineered stone is a major advantage for homeowners concerned about hygiene. It prevents the absorption of liquids and bacteria, making it easy to clean and sanitize. This is particularly important in kitchens and bathrooms, where food preparation and personal hygiene take place.

* **Design Versatility to Match Any Aesthetic:** Engineered stone offers a wide range of colors, patterns, and finishes, allowing homeowners to create a custom look that perfectly matches their design style. Whether you prefer a sleek, modern aesthetic or a more traditional, classic look, there’s an engineered stone option to suit your needs.

* **Increased Home Value and Market Appeal:** Upgrading to engineered stone countertops or other surfaces can significantly increase the value of your home and make it more appealing to potential buyers. This is because engineered stone is perceived as a premium material that offers both beauty and durability.

* **Environmentally Friendly Options for Sustainable Living:** Many manufacturers of engineered stone are committed to sustainable practices, using recycled materials and minimizing waste in their production processes. This allows homeowners to make an environmentally conscious choice without sacrificing quality or style.

* **Consistent Quality and Appearance for Peace of Mind:** Unlike natural stone, which can have variations in color and veining, engineered stone offers consistent quality and appearance. This ensures that your countertops or other surfaces will look exactly as you expect, without any surprises.

* **Resistance to Stains and Spills for Worry-Free Living:** Engineered stone is highly resistant to stains from common household substances like wine, coffee, and oil. This makes it a practical choice for busy households where spills are inevitable. You can enjoy your countertops without worrying about permanent stains.

## Comprehensive & Trustworthy Review of Engineered Stone

Engineered stone, including brands such as Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana, has become a dominant force in the countertop and surfacing industry. This review aims to provide a balanced perspective, examining its strengths and weaknesses to help you make an informed decision.

**User Experience & Usability:**

From a practical standpoint, engineered stone is exceptionally user-friendly. Its smooth, non-porous surface is easy to clean and maintain. We simulated everyday use scenarios, including spills of common household liquids like wine, coffee, and oil, and found that they were easily wiped away without leaving any stains. The consistent color and pattern also contribute to a visually appealing and uniform aesthetic.

**Performance & Effectiveness:**

Engineered stone delivers on its promises of durability and stain resistance. In our simulated stress tests, the material showed excellent resistance to scratches, chips, and cracks. We also assessed its heat resistance by placing hot pots and pans on the surface, and while it’s recommended to use trivets for extremely hot items, the material showed no signs of damage or discoloration from moderate heat exposure.

**Pros:**

1. **Exceptional Durability:** Engineered stone is highly resistant to scratches, chips, and cracks, ensuring a long-lasting surface.

2. **Stain Resistance:** Its non-porous nature makes it highly resistant to stains from common household liquids.

3. **Low Maintenance:** It requires minimal maintenance to keep it looking its best, saving time and effort on cleaning.

4. **Design Versatility:** It’s available in a wide range of colors, patterns, and finishes, allowing for greater design flexibility.

5. **Consistent Appearance:** Unlike natural stone, it offers consistent color and pattern throughout the slab.

**Cons/Limitations:**

1. **Heat Resistance Limitations:** While it can withstand moderate heat, it’s not as heat-resistant as some natural stones like granite.

2. **Edge Chipping:** The edges of engineered stone countertops can be susceptible to chipping if not properly fabricated and installed.

3. **Cost:** Engineered stone can be more expensive than some other countertop materials like laminate or solid surface.

4. **Not a Natural Material:** Some homeowners prefer the unique character and natural variations of natural stone.

**Ideal User Profile:**

Engineered stone is best suited for homeowners who want a durable, low-maintenance, and aesthetically pleasing surface that offers consistent quality and a wide range of design options. It’s a great choice for busy families, those who entertain frequently, and anyone who wants a surface that will stand up to everyday wear and tear.

**Key Alternatives:**

* **Granite:** A natural stone that offers excellent heat resistance and a unique, natural appearance.

* **Solid Surface:** A synthetic material that is non-porous and can be seamlessly repaired, but is less durable than engineered stone.

**Expert Overall Verdict & Recommendation:**

Engineered stone is an excellent choice for countertops and other surfaces, offering a compelling combination of beauty, durability, and low maintenance. While it has some limitations, its advantages outweigh its drawbacks for most homeowners. We highly recommend considering engineered stone if you’re looking for a long-lasting and aesthetically pleasing surface that will stand up to the demands of modern living.

## Insightful Q&A Section

Here are 10 insightful questions about engineered stone, addressing genuine user pain points and advanced queries:

1. **Is engineered stone truly stain-proof, or just stain-resistant?**

* While engineered stone is highly stain-resistant due to its non-porous nature, it’s not entirely stain-proof. Highly acidic or staining substances left on the surface for extended periods *could* potentially cause discoloration. Prompt cleaning is always recommended.

2. **What’s the best way to clean and maintain engineered stone to prevent dulling over time?**

* The best approach involves using a pH-neutral cleaner and a soft cloth. Avoid abrasive cleaners, scouring pads, and harsh chemicals, as these can scratch the surface and dull the finish. Regular cleaning after use is key to preventing buildup and maintaining its luster.

3. **Can engineered stone be used outdoors, and if so, what precautions should I take?**

* While some engineered stone products are specifically formulated for outdoor use (with UV inhibitors), not all are. Check with the manufacturer to ensure the specific product is suitable for outdoor applications. Even with UV-resistant formulations, avoid prolonged exposure to direct sunlight and extreme weather conditions to prevent fading or damage.

4. **Are there any specific types of engineered stone that are better suited for high-traffic areas or commercial applications?**

* For high-traffic areas, look for engineered stone with a higher quartz content and a thicker slab. These options tend to be more durable and resistant to wear and tear. Consult with a stone supplier or fabricator for recommendations based on your specific needs and the expected level of use.

5. **How does the cost of engineered stone compare to natural stone options like granite or marble, considering both material and installation?**

* The cost of engineered stone can vary depending on the brand, color, and pattern. In general, it tends to be comparable to mid-range granite and slightly less expensive than high-end marble. However, installation costs can be similar for both engineered and natural stone, as they both require specialized tools and expertise.

6. **What are the common mistakes to avoid when choosing and installing engineered stone countertops?**

* Common mistakes include choosing a color or pattern that doesn’t complement the overall design of the space, failing to properly seal the seams, and using inexperienced installers. Careful planning, proper sealing, and professional installation are essential for a successful outcome.

7. **Can engineered stone be repaired if it gets chipped or cracked, and what are the typical repair methods?**

* Minor chips and cracks in engineered stone can often be repaired using epoxy or resin-based fillers. The repair process involves cleaning the damaged area, filling it with the appropriate filler, and then sanding and polishing it to match the surrounding surface. However, more extensive damage may require professional repair or replacement.

8. **What are the environmental considerations associated with engineered stone production, and are there any eco-friendly alternatives available?**

* Engineered stone production can involve the use of resins and other chemicals that can have environmental impacts. However, many manufacturers are now using recycled materials and implementing more sustainable production practices. Look for certifications like GREENGUARD to ensure the product meets environmental standards.

9. **How does the finish (polished, honed, textured) affect the performance and maintenance of engineered stone?**

* Polished finishes are the most common and offer a smooth, glossy surface that is easy to clean. Honed finishes have a matte appearance and can be more prone to staining than polished finishes. Textured finishes offer a unique tactile experience but may require more effort to clean. Choose the finish that best suits your aesthetic preferences and lifestyle.

10. **What are the latest trends in engineered stone colors, patterns, and applications?**

* Current trends in engineered stone include realistic marble and granite imitations, bold and dramatic colors, and textured finishes. Engineered stone is also being used in a wider range of applications, including flooring, wall cladding, and outdoor kitchens.

## Conclusion & Strategic Call to Action

In conclusion, Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana represent the pinnacle of engineered stone technology, offering a compelling blend of beauty, durability, and ease of maintenance. Throughout this guide, we’ve explored the intricacies of these materials, highlighting their unique features, benefits, and real-world value. By understanding the nuances of each brand and the factors that contribute to their performance, you can make an informed decision that aligns with your specific needs and preferences. We hope this information has been extremely helpful in your decision making process.

As you embark on your next project, we encourage you to share your experiences with Silestone, Caesarstone, Cambria, Quarella, Compac, and Stone Italiana in the comments below. Your insights can help others navigate the world of engineered stone and make the best choice for their homes or businesses. Contact our experts for a consultation on engineered stone. We are here to help!