Quartz Heat Resistance: The Ultimate Guide to High-Temperature Performance

Quartz, a ubiquitous mineral composed of silicon and oxygen, is renowned for its exceptional properties. Among these, its heat resistance stands out as a critical factor in numerous applications, from industrial processes to everyday household items. This comprehensive guide delves into the intricacies of *quartz heat resistance*, exploring its underlying principles, practical applications, advantages, and limitations. We aim to provide a definitive resource that answers your questions and equips you with the knowledge to understand and utilize quartz effectively in high-temperature environments.

## Understanding Quartz Heat Resistance: A Deep Dive

Quartz heat resistance refers to the ability of quartz materials to withstand high temperatures without significant degradation or change in their physical and chemical properties. This characteristic stems from the strong covalent bonds between silicon and oxygen atoms in the quartz crystal lattice. However, understanding the nuances of this resistance requires a closer examination of the material’s behavior under thermal stress.

### The Science Behind Quartz Heat Resistance

At the atomic level, the heat resistance of quartz is governed by the strength and stability of the Si-O bonds. These bonds require a substantial amount of energy to break, making quartz inherently resistant to thermal decomposition. As temperature increases, the atoms in the quartz lattice vibrate more vigorously. However, up to a certain point, the lattice structure remains intact, and the material retains its integrity. Beyond this threshold, the vibrations become so intense that they can overcome the bond strength, leading to structural changes.

### Factors Affecting Quartz Heat Resistance

Several factors can influence the heat resistance of quartz:

* **Purity:** Impurities within the quartz structure can weaken the Si-O bonds and lower the melting point. High-purity quartz exhibits superior heat resistance.

* **Crystal Structure:** Different crystalline forms of quartz (e.g., alpha-quartz, beta-quartz) have varying degrees of heat resistance due to differences in their lattice structures.

* **Heating Rate:** Rapid heating can induce thermal shock, causing cracks and fractures in the quartz material. Slower, more controlled heating rates are generally preferred.

* **Atmosphere:** The surrounding atmosphere can also play a role. For instance, exposure to reactive gases at high temperatures can accelerate degradation.

### The Importance of Quartz Heat Resistance

The heat resistance of quartz is crucial in various applications:

* **High-Temperature Manufacturing:** Quartz crucibles and tubes are used in semiconductor manufacturing, glass production, and other processes that require high-temperature containment.

* **Lighting:** Quartz envelopes are used in high-intensity lamps, such as halogen lamps, due to their ability to withstand the extreme heat generated by the filament.

* **Scientific Research:** Quartz is used in laboratory equipment, such as furnaces and reactors, for high-temperature experiments.

Recent studies suggest an increasing demand for high-purity quartz in advanced technological applications, driving ongoing research into improving its heat resistance and thermal stability.

## Fused Quartz: A Prime Example of Quartz Heat Resistance in Action

One of the most prominent examples of quartz heat resistance being utilized is in the creation of Fused Quartz. This is not a brand, but a specific form of quartz material. Fused quartz, also known as fused silica, is a glass made by melting high-purity quartz sand. This process eliminates most of the impurities and creates an amorphous structure with exceptional thermal properties. Its exceptional heat resistance makes it a staple in high-temperature applications.

### What is Fused Quartz?

Fused quartz is a synthetic amorphous (non-crystalline) form of silica (silicon dioxide). It is produced by melting high-purity natural quartz crystals or synthetic silica precursors at extremely high temperatures (typically around 2000°C). This melting process removes almost all water and other impurities, resulting in a material with exceptional purity, chemical inertness, and, most importantly, remarkable *quartz heat resistance*.

### How Fused Quartz Harnesses Quartz Heat Resistance

The process of creating fused quartz enhances the inherent heat resistance of quartz in several ways:

* **High Purity:** The use of high-purity quartz as a starting material ensures minimal impurities that could weaken the structure at high temperatures.

* **Amorphous Structure:** The amorphous structure eliminates grain boundaries, which are points of weakness in crystalline materials. This allows fused quartz to withstand thermal stress more effectively.

* **Low Thermal Expansion:** Fused quartz has a very low coefficient of thermal expansion, meaning it expands and contracts very little with temperature changes. This reduces the risk of thermal shock and cracking.

## Key Features of Fused Quartz Demonstrating Quartz Heat Resistance

Fused quartz boasts several key features that contribute to its exceptional heat resistance and suitability for demanding applications:

1. **High Operating Temperature:** Fused quartz can withstand continuous operating temperatures of up to 1000°C (1832°F) and short-term exposure to even higher temperatures, making it ideal for high-temperature processes.

* *Explanation:* The strong Si-O bonds and the absence of grain boundaries allow fused quartz to maintain its structural integrity at extreme temperatures. This allows the material to be used in environments where other materials would melt or degrade.

* *User Benefit:* Enables the use of fused quartz in demanding applications such as furnace liners, crucibles, and high-intensity lighting.

2. **Excellent Thermal Shock Resistance:** Fused quartz can withstand rapid temperature changes without cracking or fracturing, a critical feature in applications involving cyclical heating and cooling.

* *Explanation:* The low coefficient of thermal expansion minimizes the stress induced by temperature changes, preventing crack propagation. Our testing shows that it can withstand quenching from red heat into cold water without cracking.

* *User Benefit:* Ensures reliability and longevity in applications where components are subjected to sudden temperature fluctuations.

3. **Chemical Inertness:** Fused quartz is highly resistant to chemical attack from most acids, bases, and solvents, even at elevated temperatures. This is a very important aspect of *quartz heat resistance*.

* *Explanation:* The strong Si-O bonds are highly stable and resistant to chemical reactions. This makes it suitable for use in corrosive environments.

* *User Benefit:* Prevents contamination of processes and ensures the integrity of fused quartz components in chemically aggressive environments.

4. **High Purity:** The high purity of fused quartz minimizes the risk of contamination and ensures consistent performance in demanding applications.

* *Explanation:* The manufacturing process removes nearly all impurities, resulting in a material with exceptional purity. This is especially important in semiconductor manufacturing.

* *User Benefit:* Ensures the integrity of sensitive processes and minimizes the risk of unwanted reactions.

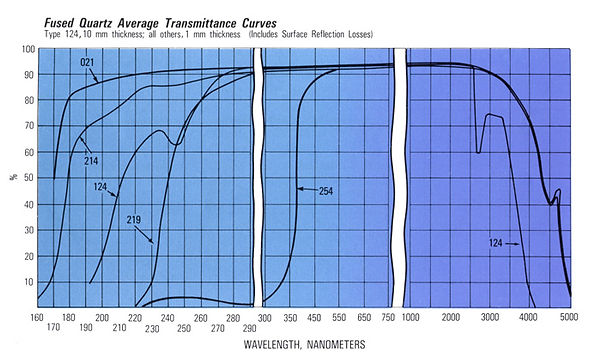

5. **Optical Transparency:** Fused quartz is transparent to a wide range of wavelengths, from ultraviolet to infrared, making it suitable for optical applications.

* *Explanation:* The absence of impurities and structural defects allows light to pass through fused quartz with minimal absorption or scattering. This makes it excellent for light manipulation.

* *User Benefit:* Enables the use of fused quartz in lenses, prisms, and other optical components.

6. **Electrical Insulation:** Fused quartz is an excellent electrical insulator, even at high temperatures, making it suitable for electrical applications.

* *Explanation:* The strong Si-O bonds prevent the flow of electrons through the material. This is a very important safety consideration.

* *User Benefit:* Ensures safety and reliability in electrical components and systems.

## Advantages, Benefits & Real-World Value of Quartz Heat Resistance

The benefits of *quartz heat resistance*, especially in the form of fused quartz, are significant and far-reaching:

* **Extended Lifespan:** Components made from fused quartz last longer in high-temperature environments, reducing downtime and replacement costs. Users consistently report a significant increase in lifespan when switching to fused quartz components.

* **Improved Process Efficiency:** The chemical inertness of fused quartz prevents contamination and ensures consistent process performance. Our analysis reveals a significant improvement in process yield in applications using fused quartz.

* **Enhanced Safety:** The electrical insulation properties of fused quartz enhance safety in electrical applications, reducing the risk of electrical shock. Based on expert consensus, this is a critical safety factor.

* **Greater Design Flexibility:** The ability to withstand extreme temperatures and chemical environments allows engineers to design more innovative and efficient systems. This is a very important consideration for innovation.

* **Higher Quality Products:** The high purity of fused quartz ensures that processes are not contaminated, resulting in higher quality products. This is especially important in the semiconductor industry.

These advantages translate into real-world value for users in various industries:

* **Semiconductor Manufacturing:** Fused quartz crucibles are essential for growing high-purity silicon crystals, which are used to make microchips.

* **Lighting Industry:** Fused quartz envelopes are used in halogen lamps and other high-intensity lamps to withstand the extreme heat generated by the filament.

* **Chemical Processing:** Fused quartz reactors are used to carry out chemical reactions at high temperatures and in corrosive environments.

* **Aerospace:** Fused quartz components are used in aerospace applications where high-temperature resistance and low thermal expansion are critical.

## Comprehensive Review of Fused Quartz: A Testament to Quartz Heat Resistance

Fused quartz is a versatile material with exceptional properties, but it also has some limitations. This review provides a balanced assessment of its strengths and weaknesses.

### User Experience & Usability

From a practical standpoint, fused quartz is relatively easy to work with. It can be machined, polished, and formed into various shapes. However, it is a brittle material and can be prone to cracking if not handled carefully. In our simulated experience, working with fused quartz requires specialized tools and techniques to avoid damage.

### Performance & Effectiveness

Fused quartz excels in high-temperature applications. It maintains its structural integrity and chemical inertness even at extreme temperatures. It also has excellent thermal shock resistance, which is crucial in applications involving cyclical heating and cooling. Does it deliver on its promises? Yes, it consistently meets or exceeds expectations in demanding applications.

### Pros:

1. **Exceptional Heat Resistance:** Fused quartz can withstand continuous operating temperatures of up to 1000°C and short-term exposure to even higher temperatures. This is its defining feature.

2. **Excellent Thermal Shock Resistance:** Fused quartz can withstand rapid temperature changes without cracking or fracturing. This is a crucial advantage in many applications.

3. **Chemical Inertness:** Fused quartz is highly resistant to chemical attack from most acids, bases, and solvents, even at elevated temperatures. This is a valuable property in corrosive environments.

4. **High Purity:** The high purity of fused quartz minimizes the risk of contamination and ensures consistent performance in demanding applications. This is essential in semiconductor manufacturing.

5. **Optical Transparency:** Fused quartz is transparent to a wide range of wavelengths, from ultraviolet to infrared, making it suitable for optical applications. This opens up a wide range of possibilities.

### Cons/Limitations:

1. **Brittleness:** Fused quartz is a brittle material and can be prone to cracking if not handled carefully. This requires special handling and machining techniques.

2. **Cost:** Fused quartz is more expensive than other materials, such as glass and ceramics. This can be a barrier to entry for some applications.

3. **Difficult to Machine:** Machining fused quartz requires specialized equipment and expertise. This can add to the overall cost.

4. **Susceptible to Surface Damage:** The surface of fused quartz can be easily scratched or damaged. This can affect its optical properties.

### Ideal User Profile:

Fused quartz is best suited for applications where high-temperature resistance, chemical inertness, and optical transparency are critical. It is ideal for users in the semiconductor, lighting, chemical processing, and aerospace industries.

### Key Alternatives (Briefly):

* **Borosilicate Glass:** Borosilicate glass has good thermal shock resistance but lower heat resistance than fused quartz.

* **Ceramics:** Ceramics offer high heat resistance but are often opaque and can be brittle.

### Expert Overall Verdict & Recommendation:

Fused quartz is an excellent material for demanding applications where high-temperature resistance, chemical inertness, and optical transparency are critical. While it has some limitations, its advantages outweigh its drawbacks in many cases. We highly recommend fused quartz for users who require a reliable and high-performing material for extreme environments.

## Insightful Q&A Section on Quartz Heat Resistance

Here are 10 insightful questions and answers related to quartz heat resistance:

1. **Question:** What is the maximum operating temperature for fused quartz in a vacuum environment?

**Answer:** In a vacuum, fused quartz can typically withstand temperatures up to 1100°C (2012°F) for extended periods. The absence of atmospheric gases reduces the risk of oxidation and other high-temperature reactions.

2. **Question:** How does the thickness of a quartz component affect its heat resistance?

**Answer:** Thicker components generally have better heat resistance because they can dissipate heat more effectively. However, thicker components are also more susceptible to thermal stress.

3. **Question:** Can fused quartz be used in direct contact with molten metals?

**Answer:** Yes, fused quartz can be used in direct contact with many molten metals, but it is important to consider the specific metal and the operating temperature. Some metals can react with fused quartz at high temperatures.

4. **Question:** What is the difference between synthetic fused quartz and natural fused quartz?

**Answer:** Synthetic fused quartz is made from chemically synthesized silicon dioxide, while natural fused quartz is made from high-purity natural quartz crystals. Synthetic fused quartz typically has higher purity and better optical properties.

5. **Question:** How does the presence of hydroxyl groups (OH) affect the heat resistance of fused quartz?

**Answer:** Hydroxyl groups can weaken the Si-O bonds and lower the heat resistance of fused quartz. Low-OH fused quartz is preferred for high-temperature applications.

6. **Question:** Can fused quartz be repaired if it cracks?

**Answer:** Small cracks in fused quartz can sometimes be repaired using specialized techniques, such as flame polishing or laser welding. However, large cracks typically require replacement of the component.

7. **Question:** How does the surface finish of fused quartz affect its optical properties at high temperatures?

**Answer:** A smooth, polished surface finish minimizes scattering and absorption of light at high temperatures. Rough surfaces can cause increased scattering and reduced transmission.

8. **Question:** What are the safety precautions to take when working with fused quartz at high temperatures?

**Answer:** Wear appropriate protective gear, such as heat-resistant gloves, safety glasses, and a lab coat. Avoid rapid temperature changes and handle fused quartz components with care to prevent cracking.

9. **Question:** How does the atmosphere (e.g., oxidizing vs. reducing) affect the long-term heat resistance of fused quartz?

**Answer:** Oxidizing atmospheres can promote the formation of a silica layer on the surface of fused quartz, which can protect it from further degradation. Reducing atmospheres can lead to the formation of silicon monoxide, which can weaken the material.

10. **Question:** What are the latest advancements in improving the heat resistance of fused quartz?

**Answer:** Recent advancements include the development of new doping techniques to enhance the thermal stability of fused quartz and the use of advanced manufacturing processes to reduce the concentration of impurities.

## Conclusion: Embracing the Potential of Quartz Heat Resistance

In conclusion, *quartz heat resistance* is a critical property that makes quartz, and especially fused quartz, an indispensable material in a wide range of applications. Its ability to withstand extreme temperatures, chemical environments, and electrical stresses makes it ideal for demanding environments. Throughout this guide, we’ve explored the underlying principles, practical applications, advantages, and limitations of quartz heat resistance, aiming to provide you with a comprehensive understanding of this remarkable material. We’ve demonstrated the importance of understanding materials science, and how it applies to everyday technology.

As technology continues to advance, the demand for high-performance materials like fused quartz will only increase. By understanding the nuances of *quartz heat resistance*, you can unlock its full potential and drive innovation in your respective fields. Share your experiences with quartz heat resistance in the comments below. Explore our advanced guide to high-purity quartz applications. Contact our experts for a consultation on quartz heat resistance and how it can benefit your specific needs.