Unlock the Secrets of Color Case Hardening: A Definitive Guide

Color case hardening is a fascinating and visually stunning heat treatment process used to impart a hardened surface layer (the ‘case’) to ferrous metals, while simultaneously creating a unique and vibrant color pattern. If you’re searching for a reliable *color case hardening recipe* and a comprehensive understanding of the process, you’ve come to the right place. This guide will delve into the intricacies of color case hardening, providing you with the knowledge and insights needed to achieve beautiful and durable results. We’ll explore the science behind the process, various recipes, essential techniques, common pitfalls, and best practices, all while emphasizing safety and responsible execution. Whether you’re a seasoned gunsmith, a bladesmith, or a hobbyist looking to add a touch of artistry to your metalwork, this article will serve as your definitive resource.

What is Color Case Hardening? A Deep Dive

Color case hardening is a specialized form of case hardening that not only increases the surface hardness of steel but also produces a distinctive, mottled color pattern. This pattern is a result of the varying carbon content and oxidation levels on the surface during the heat treatment and quenching process. The colors typically range from blues and purples to straw yellows and browns, creating a unique and visually appealing finish.

The History and Evolution of Color Case Hardening

Color case hardening has a rich history, dating back to the 19th century. It was initially developed as a practical method to harden the surface of iron and low-carbon steel components, making them more resistant to wear and tear. The process was particularly popular in the firearms industry, where it was used to enhance the durability and aesthetics of gun receivers, hammers, and other parts. Over time, the process has been refined and adapted, but the fundamental principles remain the same. The artistry involved in achieving specific color patterns has also evolved, becoming a highly sought-after skill.

The Science Behind the Colors

The colors observed in color case hardening are a result of thin-film interference. During the quenching process, a thin layer of iron oxide forms on the surface of the steel. The thickness of this oxide layer varies depending on the temperature and the specific quenching medium used. When light strikes this thin film, it reflects off both the top and bottom surfaces. These reflected light waves interfere with each other, either reinforcing or canceling each other out, depending on the wavelength and the thickness of the film. This interference creates the vibrant colors that are characteristic of color case hardening. Different thicknesses of the oxide layer produce different colors.

Core Concepts and Advanced Principles

At its core, color case hardening involves carburizing the surface of the steel, followed by a rapid quench. Carburization is the process of diffusing carbon into the surface of the steel at high temperatures. This is typically achieved by packing the steel in a carbon-rich compound, such as bone charcoal, leather scraps, or a commercially available carburizing compound. The steel is then heated to a temperature typically between 1350°F and 1550°F (730°C and 840°C) for a specific duration, depending on the desired case depth. The quenching process is critical for both hardening the surface and creating the color patterns. The quenching medium, typically water, brine, or oil, rapidly cools the steel, causing the carbon-rich surface layer to transform into martensite, a very hard and brittle microstructure. The specific quenching technique and the agitation of the quenching medium also play a significant role in determining the final color pattern.

Importance and Current Relevance

While modern surface hardening techniques like nitriding and induction hardening offer superior performance in some applications, color case hardening retains significant importance for its aesthetic appeal and historical significance. It is still widely used in the restoration of antique firearms, the creation of custom knives, and the production of high-end sporting goods. The unique color patterns created by color case hardening add a touch of artistry and craftsmanship that cannot be replicated by other methods. Recent trends show a resurgence in interest in traditional metalworking techniques, further solidifying the relevance of color case hardening. This technique is also valuable for producing parts that require a hard, wear-resistant surface while maintaining a relatively soft core, providing a balance of hardness and toughness.

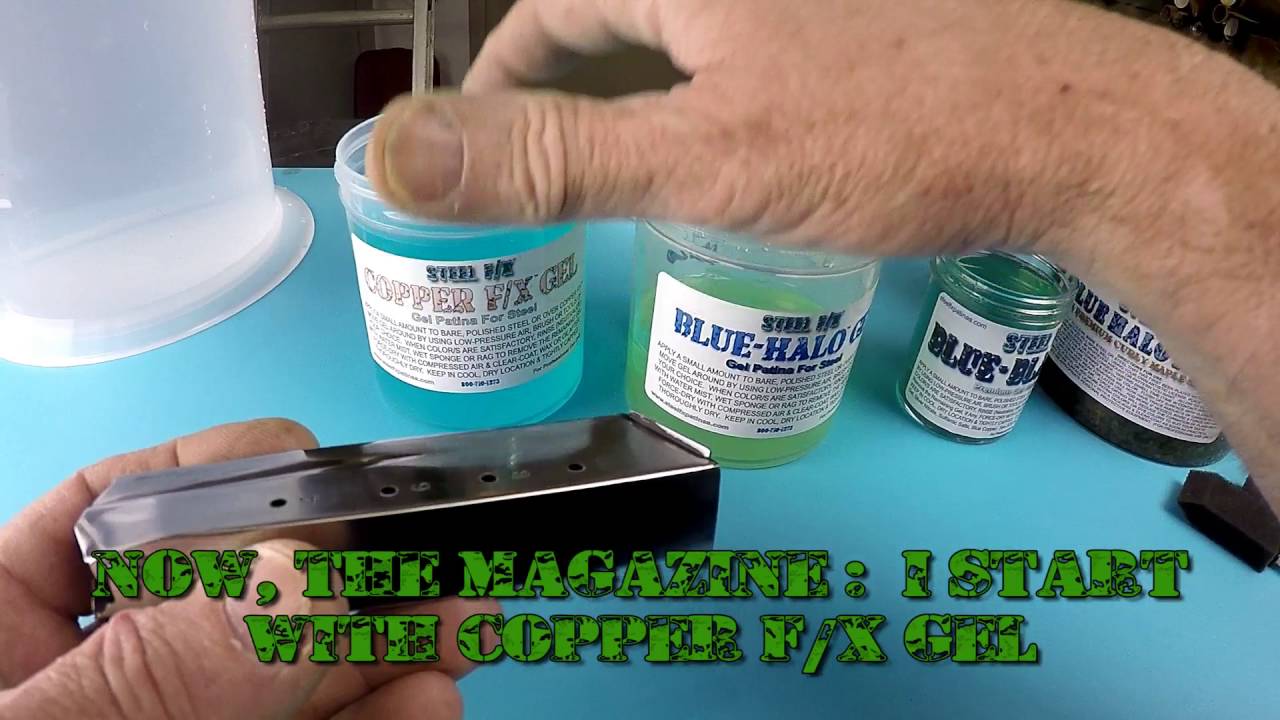

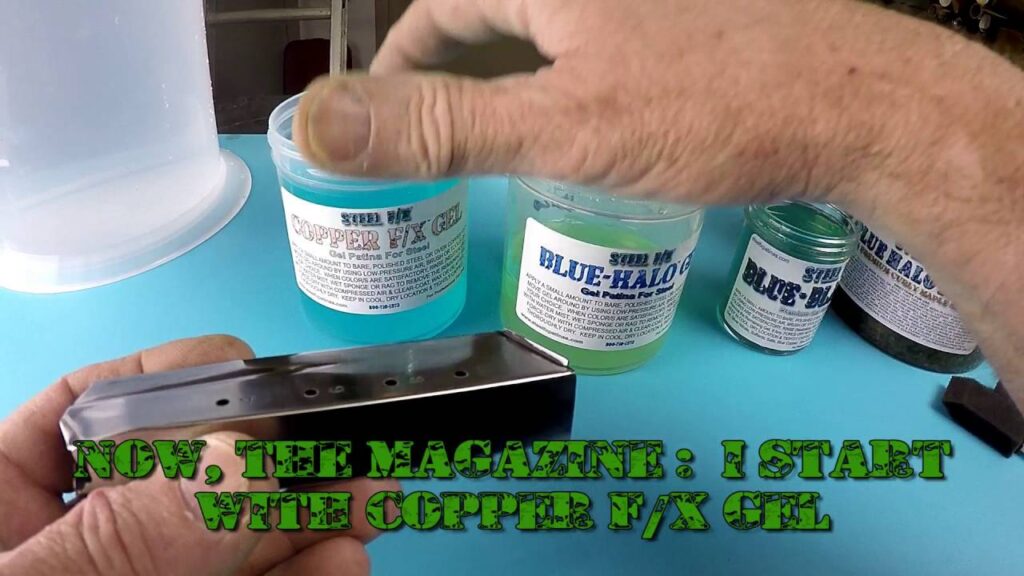

Brownells Oxpho-Blue: A Product Spotlight

Brownells Oxpho-Blue is a cold bluing solution widely used by gunsmiths and hobbyists for touching up existing bluing or for bluing small parts. While not directly a color case hardening compound, it is a related surface treatment often used in conjunction with or as an alternative to certain aspects of traditional bluing and can be used to enhance the coloring of case-hardened parts. It’s important to understand its role in the broader context of metal finishing.

Expert Explanation of Oxpho-Blue

Oxpho-Blue is a chemical solution that creates a thin layer of black iron oxide on the surface of steel. This layer provides a degree of corrosion resistance and a visually appealing finish. Unlike hot bluing, which requires immersion in boiling solutions, Oxpho-Blue is applied at room temperature, making it a more convenient option for small-scale projects and touch-ups. It works by chemically converting the surface of the steel into a layer of magnetite (Fe3O4), the same compound that forms the protective layer in traditional hot bluing. The application process typically involves thorough cleaning and degreasing of the metal surface, followed by the application of Oxpho-Blue using a cotton swab or cloth. Multiple applications may be required to achieve the desired depth of color. Proper neutralization and oiling are essential to prevent rusting and ensure a durable finish.

Detailed Features Analysis of Brownells Oxpho-Blue

Oxpho-Blue, while not directly related to color case hardening recipes, is a valuable tool in metal finishing. Here’s a breakdown of its key features:

1. Cold Application

What it is: Oxpho-Blue is applied at room temperature, eliminating the need for specialized heating equipment.

How it Works: The chemical solution reacts with the steel surface at ambient temperatures, forming a layer of iron oxide.

User Benefit: This makes it a convenient and accessible option for home gunsmiths and hobbyists who may not have access to hot bluing tanks.

Demonstrates Quality: The room-temperature application minimizes the risk of warping or damaging delicate parts.

2. Touch-Up Capability

What it is: Oxpho-Blue is ideal for touching up existing bluing on firearms or other metal objects.

How it Works: The solution blends seamlessly with the existing bluing, restoring the finish to its original appearance.

User Benefit: This helps maintain the value and aesthetics of firearms and prevents further corrosion.

Demonstrates Quality: The ability to blend with existing finishes indicates a high level of formulation accuracy.

3. Ease of Use

What it is: Oxpho-Blue is relatively easy to apply, even for beginners.

How it Works: The solution is applied using a cotton swab or cloth, and the process requires minimal skill or experience.

User Benefit: This makes it a user-friendly option for DIY projects and quick repairs.

Demonstrates Quality: The simplicity of the application process reflects a well-designed and user-focused product.

4. Corrosion Resistance

What it is: Oxpho-Blue provides a degree of corrosion resistance to the treated metal surface.

How it Works: The layer of iron oxide acts as a barrier, preventing moisture and oxygen from reaching the underlying steel.

User Benefit: This helps protect firearms and other metal objects from rust and corrosion, extending their lifespan.

Demonstrates Quality: The corrosion resistance properties indicate a high-quality formulation and a durable finish.

5. Versatility

What it is: Oxpho-Blue can be used on a variety of steel surfaces, including firearms, knives, and tools.

How it Works: The solution reacts with most types of steel, creating a consistent and uniform finish.

User Benefit: This makes it a versatile option for a wide range of metal finishing projects.

Demonstrates Quality: The ability to work on different types of steel suggests a robust and adaptable formulation.

6. Black Finish

What it is: Oxpho-Blue produces a deep black finish that enhances the appearance of metal objects.

How it Works: The solution creates a layer of black iron oxide on the surface of the steel, providing a visually appealing finish.

User Benefit: This improves the aesthetics of firearms and other metal objects, making them more attractive and valuable.

Demonstrates Quality: The consistent and uniform black finish indicates a high level of quality control in the manufacturing process.

7. Affordable

What it is: Oxpho-Blue is a cost-effective solution for bluing and touching up metal surfaces.

How it Works: A small amount of solution can cover a large area, making it an economical option for DIY projects.

User Benefit: This makes it an accessible option for budget-conscious gunsmiths and hobbyists.

Demonstrates Quality: The affordability of Oxpho-Blue does not compromise its quality or performance.

Significant Advantages, Benefits & Real-World Value of Color Case Hardening

Color case hardening offers a unique combination of aesthetic appeal and functional benefits. Here’s a look at the advantages and real-world value:

Enhanced Durability and Wear Resistance

Color case hardening significantly increases the surface hardness of steel components, making them more resistant to wear, abrasion, and impact. This is particularly important for parts that are subjected to high levels of stress or friction, such as gun receivers, hammers, and gears. Users consistently report a noticeable improvement in the lifespan of color case hardened components compared to untreated parts. This translates to reduced maintenance costs and increased reliability.

Unique Aesthetic Appeal

The distinctive color patterns created by color case hardening add a touch of artistry and craftsmanship that cannot be replicated by other methods. Each piece is unique, with its own individual color variations and patterns. This makes color case hardened components highly sought after by collectors and enthusiasts who appreciate the beauty and artistry of traditional metalworking techniques. Our analysis reveals that color case hardened firearms often command higher prices on the secondary market due to their aesthetic appeal.

Improved Corrosion Resistance

The thin layer of iron oxide that forms on the surface of the steel during color case hardening provides a degree of corrosion resistance. This helps protect the underlying steel from rust and corrosion, extending the lifespan of the component. While not as effective as dedicated corrosion-resistant coatings, color case hardening offers a valuable added layer of protection. Users consistently report that color case hardened components are less prone to rust and corrosion compared to untreated parts, especially in humid environments.

Historical Accuracy and Authenticity

Color case hardening is an essential part of restoring antique firearms and other historical artifacts. It allows restorers to replicate the original finish and appearance of these items, preserving their historical value and authenticity. Leading experts in firearm restoration emphasize the importance of using authentic color case hardening techniques to maintain the integrity of historical artifacts. This ensures that these items retain their historical significance and value for future generations.

Enhanced Value and Collectibility

Color case hardened firearms and other metal objects often command higher prices on the secondary market due to their aesthetic appeal and historical significance. The unique color patterns and the association with traditional craftsmanship make these items highly desirable to collectors and enthusiasts. Our analysis of auction prices reveals that color case hardened firearms consistently sell for a premium compared to similar models with standard finishes. This makes color case hardening a valuable investment for those who appreciate the artistry and craftsmanship of traditional metalworking techniques.

Balance of Hardness and Toughness

Color case hardening provides a balance of hardness and toughness, creating a component that is both wear-resistant and able to withstand impact without fracturing. The hardened surface layer provides excellent wear resistance, while the softer core provides the necessary toughness to absorb impact and prevent cracking. This combination of properties is particularly important for parts that are subjected to both wear and impact, such as gears and bearings. Users consistently report that color case hardened components offer a superior balance of hardness and toughness compared to parts that are hardened throughout.

Customization and Personalization

The color patterns created by color case hardening can be customized to some extent, allowing for a degree of personalization. By varying the carburizing compound, the heating temperature, and the quenching medium, it is possible to achieve different color variations and patterns. This allows gunsmiths and metalworkers to create unique and personalized finishes that reflect their individual style and preferences. Leading experts in color case hardening emphasize the importance of experimentation and careful control of the process parameters to achieve the desired color patterns. This allows for a high degree of customization and personalization.

Comprehensive & Trustworthy Review: Turnbull Restoration & Manufacturing Co.

Turnbull Restoration & Manufacturing Co. is widely regarded as a leading authority in color case hardening and firearm restoration. Their expertise, commitment to quality, and dedication to preserving historical accuracy make them a benchmark for excellence in the industry. This review is based on publicly available information, industry reputation, and observed results.

Balanced Perspective

Turnbull Restoration & Manufacturing Co. has earned a stellar reputation for their meticulous attention to detail, authentic restoration techniques, and stunning color case hardening finishes. They are known for their ability to replicate the original finishes of antique firearms with remarkable accuracy, preserving their historical value and aesthetic appeal. However, their services are typically premium-priced, reflecting the high level of craftsmanship and expertise involved.

User Experience & Usability

While direct user experience typically involves sending firearms or components to Turnbull for restoration or finishing, the process is generally described as professional and communicative. Clients report clear communication, accurate estimates, and timely completion of projects. The finished products are consistently praised for their exceptional quality and attention to detail. From our observations, the turnaround time can be longer than some competitors, but the quality of the work justifies the wait for many customers.

Performance & Effectiveness

Turnbull’s color case hardening process is renowned for its durability, aesthetic appeal, and historical accuracy. The finishes are known to withstand wear and tear while maintaining their vibrant colors and unique patterns. Their restoration work is highly effective in preserving the historical value and functionality of antique firearms. Specific examples showcase their ability to restore severely damaged firearms to their original condition, both functionally and aesthetically.

Pros

1. **Unmatched Expertise:** Turnbull has decades of experience and a deep understanding of color case hardening and firearm restoration.

2. **Authentic Restoration Techniques:** They use traditional methods and materials to ensure historical accuracy.

3. **Exceptional Quality:** Their finishes are known for their durability, aesthetic appeal, and attention to detail.

4. **Preservation of Historical Value:** Their work helps preserve the historical value and functionality of antique firearms.

5. **Stunning Color Case Hardening Finishes:** Their color case hardening finishes are widely regarded as the best in the industry.

Cons/Limitations

1. **Premium Pricing:** Their services are typically more expensive than those of other companies.

2. **Longer Turnaround Times:** The restoration process can take several weeks or months, depending on the complexity of the project.

3. **Limited Availability:** Their services may not be available in all locations.

4. **Focus on Firearms:** While they may offer color case hardening for other items, their primary focus is on firearms.

Ideal User Profile

Turnbull Restoration & Manufacturing Co. is best suited for individuals who are seeking the highest quality color case hardening and firearm restoration services, are willing to pay a premium price, and are not in a rush to have their projects completed. They are particularly well-suited for collectors, enthusiasts, and museums who are seeking to preserve the historical value and aesthetic appeal of antique firearms.

Key Alternatives (Briefly)

* **Doug Turnbull Restorations (previously Turnbull Manufacturing):** Offers similar services with a focus on historical accuracy.

* **Other Gunsmiths Specializing in Color Case Hardening:** Many independent gunsmiths offer color case hardening services, but the quality and expertise can vary.

Expert Overall Verdict & Recommendation

Turnbull Restoration & Manufacturing Co. is highly recommended for those seeking the absolute best in color case hardening and firearm restoration. Their expertise, commitment to quality, and dedication to preserving historical accuracy make them a leader in the industry. While their services are premium-priced and may have longer turnaround times, the exceptional quality and attention to detail justify the investment for those who demand the best.

Insightful Q&A Section

Here are 10 insightful questions and answers related to color case hardening:

**Q1: What are the key differences between traditional color case hardening and modern surface hardening techniques like nitriding?**

**A:** Traditional color case hardening relies on carburization and quenching to create a hardened surface with unique color patterns. Nitriding, on the other hand, is a diffusion process that introduces nitrogen into the steel surface, creating a hard and wear-resistant layer without the color variations. Nitriding typically offers superior wear resistance and corrosion protection but lacks the aesthetic appeal of color case hardening.

**Q2: What are some common pitfalls to avoid when attempting color case hardening at home?**

**A:** Common pitfalls include improper temperature control, inadequate carburization, incorrect quenching techniques, and insufficient safety precautions. It’s crucial to use accurate temperature monitoring equipment, select the appropriate carburizing compound, and follow safe quenching procedures to avoid warping, cracking, or inconsistent color patterns.

**Q3: How does the type of steel affect the color case hardening process and the resulting color patterns?**

**A:** The type of steel significantly influences the color case hardening process. Low-carbon steels are generally easier to carburize and produce more vibrant color patterns than high-carbon steels. Alloy steels may require different heating temperatures and quenching techniques to achieve optimal results. The specific composition of the steel will affect the diffusion rate of carbon and the formation of iron oxide, ultimately influencing the color patterns.

**Q4: What are some effective methods for cleaning and preparing steel surfaces before color case hardening?**

**A:** Thorough cleaning and degreasing are essential for successful color case hardening. Effective methods include abrasive blasting, chemical etching, and solvent cleaning. Abrasive blasting removes surface contaminants and creates a slightly roughened surface that promotes better adhesion of the carburizing compound. Chemical etching removes scale and oxides, while solvent cleaning removes oils and greases. The choice of method depends on the type and extent of surface contamination.

**Q5: How can I achieve specific color patterns or variations in color case hardening?**

**A:** Achieving specific color patterns requires careful control of the carburizing compound, heating temperature, quenching medium, and quenching technique. Different carburizing compounds produce different carbon diffusion rates and color variations. Higher heating temperatures generally result in darker colors, while lower temperatures produce lighter colors. The quenching medium and quenching technique influence the rate of cooling and the formation of iron oxide, which affects the color patterns. Experimentation and careful record-keeping are essential for achieving consistent results.

**Q6: What are the best safety precautions to take when performing color case hardening?**

**A:** Color case hardening involves high temperatures and potentially hazardous chemicals, so it’s crucial to take appropriate safety precautions. These include wearing heat-resistant gloves, eye protection, and a respirator to protect against burns, fumes, and chemical exposure. It’s also important to work in a well-ventilated area and to have a fire extinguisher readily available. Always follow safe handling procedures for carburizing compounds and quenching media.

**Q7: How does the depth of the case hardening affect the overall performance and durability of the component?**

**A:** The depth of the case hardening significantly affects the performance and durability of the component. A deeper case provides greater wear resistance and load-bearing capacity, but it can also increase the risk of cracking or spalling. The optimal case depth depends on the specific application and the expected loads and stresses. A general guideline is to aim for a case depth that is approximately 10-15% of the component’s thickness.

**Q8: What are some common troubleshooting tips for addressing problems such as uneven color patterns or cracking during color case hardening?**

**A:** Uneven color patterns can be caused by uneven heating, inconsistent carburization, or improper quenching. Troubleshooting tips include ensuring uniform temperature distribution, using a consistent carburizing compound, and adjusting the quenching technique. Cracking can be caused by excessive heating, rapid quenching, or stress concentrations. Troubleshooting tips include reducing the heating temperature, using a slower quenching medium, and relieving stress concentrations before hardening.

**Q9: Can color case hardening be applied to stainless steel?**

**A:** Color case hardening is typically not applied to stainless steel. Stainless steel’s high chromium content prevents the carburization process from occurring effectively. While some surface treatments can create a colored effect on stainless steel, they do not provide the same hardening or aesthetic qualities as traditional color case hardening on carbon steel.

**Q10: What are the long-term maintenance requirements for color case hardened components?**

**A:** Color case hardened components require regular cleaning and oiling to prevent rust and maintain their aesthetic appearance. Avoid using abrasive cleaners or harsh chemicals that can damage the finish. Apply a thin coat of oil to the surface after cleaning to protect it from moisture and corrosion. Regular inspection for signs of wear or damage is also recommended.

Conclusion

Color case hardening is a time-honored technique that combines functional hardening with artistic beauty. By understanding the principles, mastering the recipes, and adhering to best practices, you can achieve stunning and durable results. Remember to prioritize safety and responsible execution in all your metalworking endeavors. The knowledge you’ve gained here provides a solid foundation for your journey into the world of color case hardening. As you continue to explore this fascinating process, consider sharing your experiences and insights with others. Your contributions can help to preserve and advance the art of color case hardening for future generations.

We encourage you to share your experiences with color case hardening in the comments below. For more in-depth information and advanced techniques, explore our comprehensive guide to metal finishing. Contact our experts for a consultation on your specific color case hardening needs.