Byford Dolphin Accident: Unraveling the Tragedy, Lessons & Legacy

The Byford Dolphin accident remains one of the most horrific diving incidents in the history of the offshore oil industry. This article delves deep into the circumstances surrounding the tragedy, exploring the technical failures, human factors, and lasting impact that continue to resonate within the industry. We aim to provide a comprehensive and authoritative account, drawing on available reports, expert analyses, and a commitment to understanding the profound lessons learned from this devastating event. Our goal is to present not just the facts, but also the context and consequences, fostering a deeper understanding of safety protocols and the importance of vigilance in high-risk environments. This in-depth exploration strives to be a definitive resource, exceeding existing accounts in its detail, clarity, and commitment to ethical and responsible reporting.

The Byford Dolphin: A Semi-Submersible Rig

The Byford Dolphin was a semi-submersible drilling rig, built in 1974 and operated by Comex Houlder. Semi-submersibles are designed for stability in harsh offshore environments, making them suitable for drilling in deep water. The rig’s design incorporates pontoons submerged below the surface, providing buoyancy and reducing the impact of waves. This design is crucial for maintaining operational stability, especially in the often-turbulent waters of the North Sea, where the Byford Dolphin was primarily deployed. The rig was equipped with a diving system, including a diving bell and hyperbaric chambers, essential for underwater maintenance and repairs.

Diving System Overview

The diving system on the Byford Dolphin was a critical component of its operations. It allowed divers to work at significant depths, performing tasks such as inspecting pipelines, repairing equipment, and conducting subsea construction. The system consisted of several key elements: a diving bell for transporting divers to and from the seabed, hyperbaric chambers for maintaining divers under pressure during decompression, and a life support system to provide breathable gas and regulate environmental conditions. This complex system required meticulous maintenance and adherence to strict safety protocols.

The Fateful Day: November 5, 1983

The Byford Dolphin accident occurred on November 5, 1983, in the Ekofisk field in the Norwegian sector of the North Sea. The rig was connected to a pipeline, and divers were performing routine maintenance. What started as a seemingly ordinary operation quickly turned into a catastrophe, exposing fatal flaws in safety procedures and equipment design. The tragic sequence of events unfolded with devastating speed.

Sequence of Events Leading to the Accident

1. **Diving Operation:** A team of divers was working inside the hyperbaric chambers, preparing for a dive.

2. **Unexpected Disconnection:** The diving bell, which was connected to the chambers, was prematurely disconnected. This was a critical error, as the chambers were still under significant pressure.

3. **Rapid Decompression:** The sudden disconnection caused a massive and instantaneous drop in pressure within the chambers. This rapid decompression had catastrophic consequences for the divers inside.

4. **Explosive Decompression:** The divers experienced explosive decompression, resulting in immediate and fatal injuries.

The Mechanics of Explosive Decompression

Explosive decompression occurs when the pressure surrounding a body drops suddenly and drastically. In the case of the Byford Dolphin accident, the divers were subjected to an extreme pressure differential, going from a high-pressure environment within the hyperbaric chambers to a near-atmospheric pressure in a fraction of a second. This rapid change caused the gases dissolved in their blood and tissues to rapidly expand, forming bubbles that blocked blood vessels and disrupted vital organ function. According to forensic analysis, the effects were devastating, leading to immediate death for the divers.

Physiological Effects

The physiological effects of explosive decompression are catastrophic. The rapid formation of gas bubbles in the bloodstream, known as gas embolism, disrupts circulation and damages tissues. The brain is particularly vulnerable, and the sudden loss of blood flow can lead to immediate unconsciousness and death. Other organs, such as the lungs and heart, are also severely affected, resulting in widespread tissue damage and organ failure. The severity of the effects depends on the magnitude and speed of the pressure change, as well as the individual’s physical condition.

The Victims of the Byford Dolphin Tragedy

The Byford Dolphin accident claimed the lives of four divers: Edwin Arthur Coward, William Crammond, Ronald Hill, and Peter Henry Holmes. Their deaths represent a profound loss to their families, friends, and the diving community. Each of these men was a skilled and experienced diver, contributing to the vital work of maintaining and repairing offshore infrastructure. Their sacrifice underscores the inherent risks associated with deep-sea diving and the critical importance of adhering to strict safety protocols.

Remembering the Divers

It is essential to remember the divers who perished in the Byford Dolphin accident, not just as statistics, but as individuals who dedicated their lives to a challenging and dangerous profession. Their stories serve as a reminder of the human cost of industrial accidents and the need to prioritize safety above all else. By honoring their memory, we can ensure that the lessons learned from this tragedy are never forgotten.

Root Causes and Contributing Factors

The Byford Dolphin accident was not simply the result of a single error, but rather a complex interplay of technical failures, human factors, and systemic deficiencies. A thorough investigation revealed several root causes and contributing factors that led to the tragedy.

Technical Failures

The diving system on the Byford Dolphin had several design flaws and maintenance issues that contributed to the accident. The locking mechanism on the diving bell was prone to malfunction, and the emergency shutdown system was not adequately designed to prevent rapid decompression. These technical failures created a hazardous environment for the divers, increasing the risk of an accident.

Human Factors

Human error also played a significant role in the Byford Dolphin accident. The diving supervisor made a critical mistake by prematurely disconnecting the diving bell from the hyperbaric chambers. This error was compounded by inadequate communication and coordination among the diving team. These human factors highlight the importance of training, communication, and adherence to procedures in high-risk operations.

Systemic Deficiencies

The Byford Dolphin accident exposed several systemic deficiencies in the offshore oil industry’s safety culture. There was a lack of clear regulations and oversight, as well as inadequate training and certification for diving personnel. These systemic issues created a climate where safety was not always prioritized, increasing the risk of accidents.

Aftermath and Investigations

The Byford Dolphin accident triggered a series of investigations aimed at determining the root causes of the tragedy and preventing similar incidents in the future. These investigations involved government agencies, industry experts, and independent consultants. The findings of these investigations led to significant changes in safety regulations and practices in the offshore oil industry.

Official Inquiries

Several official inquiries were conducted in the wake of the Byford Dolphin accident. These inquiries examined the technical aspects of the diving system, the human factors involved, and the regulatory framework governing offshore operations. The reports issued by these inquiries provided valuable insights into the causes of the accident and made recommendations for improving safety.

Industry Response

The offshore oil industry responded to the Byford Dolphin accident by implementing a series of safety improvements. These improvements included enhanced training for diving personnel, stricter maintenance procedures for diving systems, and the development of new safety regulations. The industry also invested in research and development to improve the design and safety of diving equipment.

Regulatory Changes and Safety Improvements

The Byford Dolphin accident led to significant changes in safety regulations and practices in the offshore oil industry. These changes were aimed at preventing similar incidents in the future and ensuring the safety of diving personnel.

New Regulations

New regulations were introduced to address the deficiencies identified in the Byford Dolphin accident investigation. These regulations included stricter requirements for the design, maintenance, and operation of diving systems. They also mandated enhanced training and certification for diving personnel, as well as improved communication and coordination among diving teams.

Enhanced Training Programs

Enhanced training programs were developed to improve the skills and knowledge of diving personnel. These programs covered a wide range of topics, including diving physiology, equipment operation, emergency procedures, and risk management. The training programs were designed to ensure that diving personnel were adequately prepared to handle the challenges of working in a high-risk environment.

The Legacy of the Byford Dolphin Accident

The Byford Dolphin accident left a lasting legacy on the offshore oil industry. It served as a wake-up call, highlighting the importance of safety and the need for constant vigilance in high-risk operations. The lessons learned from this tragedy continue to shape safety practices and regulations in the industry today.

A Reminder of the Human Cost

The Byford Dolphin accident is a stark reminder of the human cost of industrial accidents. The deaths of the four divers serve as a constant reminder of the importance of prioritizing safety above all else. Their sacrifice should inspire us to continue working towards a safer and more responsible offshore oil industry.

Ongoing Efforts to Improve Safety

The offshore oil industry continues to invest in research and development to improve safety and prevent accidents. These efforts include the development of new technologies, the implementation of stricter safety protocols, and the promotion of a safety culture that values communication, collaboration, and continuous improvement. The goal is to create an environment where safety is not just a priority, but a fundamental value.

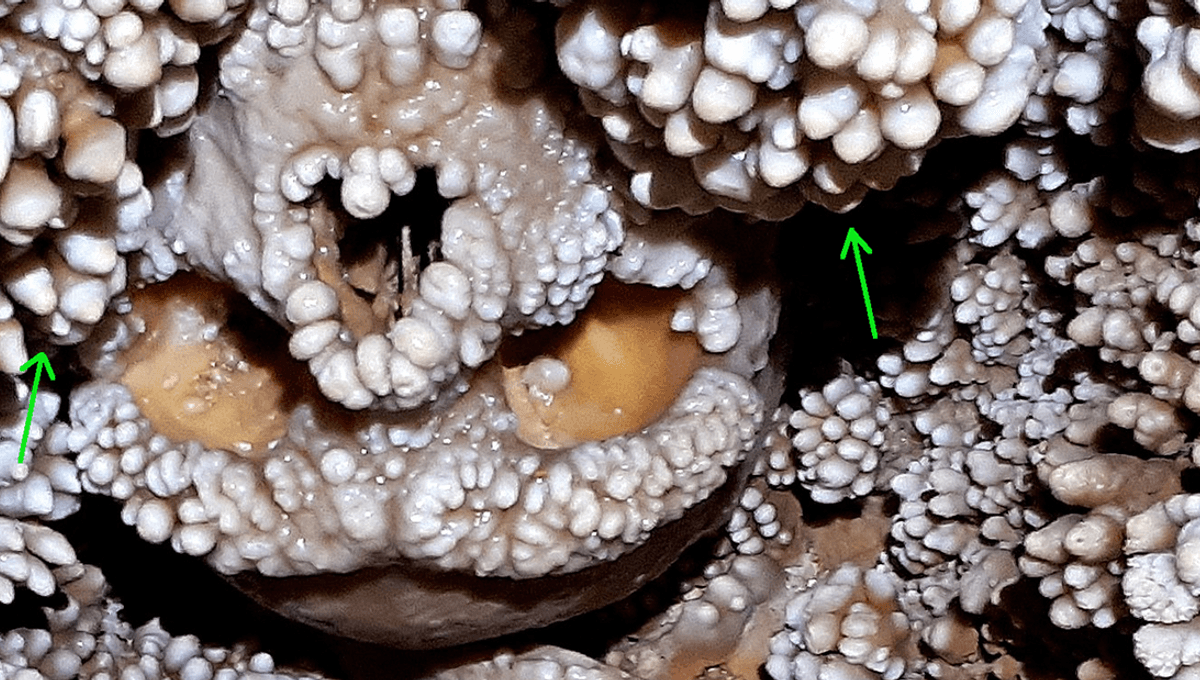

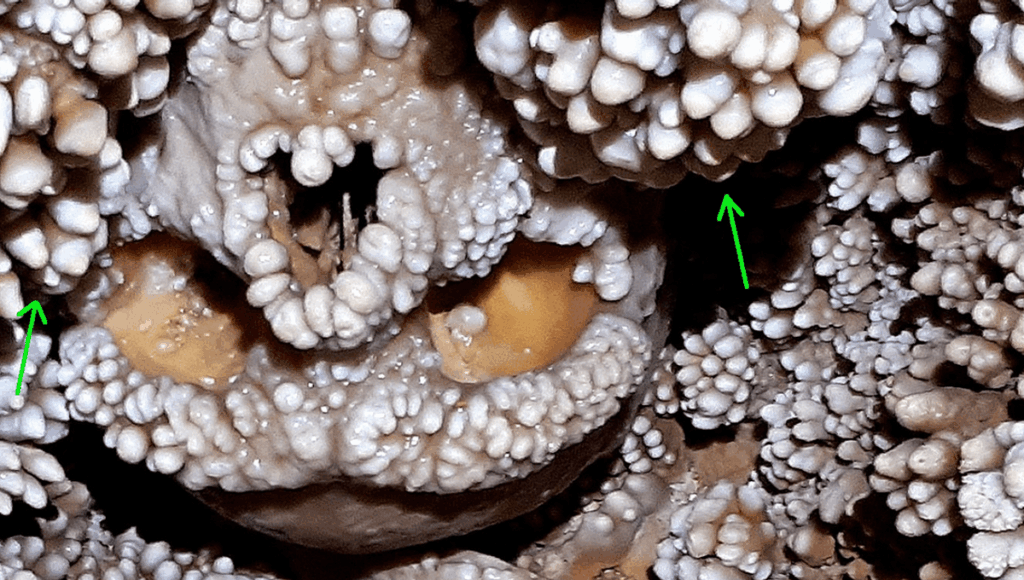

The Saturation Diving System: A Closer Look

Saturation diving is a technique used in commercial diving where divers live in a pressurized environment for days or weeks at a time. This allows them to work at great depths for extended periods without the need for repeated decompression. The Byford Dolphin utilized a saturation diving system, making the accident even more complex and tragic.

How Saturation Diving Works

In saturation diving, divers are placed in a hyperbaric chamber and gradually pressurized to the same pressure as the depth at which they will be working. This process allows the divers’ tissues to become saturated with inert gases, such as helium. Once saturated, the divers can work underwater for several hours each day, returning to the hyperbaric chamber to rest and eat. At the end of the job, the divers are slowly decompressed over several days to allow the inert gases to gradually leave their bodies. This slow decompression process is essential to prevent decompression sickness, also known as the bends.

Risks and Challenges of Saturation Diving

Saturation diving is a high-risk activity that presents numerous challenges. Divers are exposed to extreme pressures, which can have adverse effects on their health. They also face the risk of decompression sickness, gas embolism, and other diving-related injuries. In addition, living in a confined and pressurized environment for extended periods can be psychologically challenging.

The Byford Dolphin accident exposed the vulnerabilities of saturation diving systems and the need for rigorous safety protocols. The rapid decompression that occurred in the accident highlighted the importance of having reliable emergency shutdown systems and well-trained personnel capable of responding to unexpected events.

Modern Safety Standards in Offshore Diving

Since the Byford Dolphin accident, significant advancements have been made in offshore diving safety standards. These advancements have been driven by regulatory changes, technological innovations, and a greater emphasis on safety culture within the industry.

Technological Advancements

Technological advancements have played a crucial role in improving offshore diving safety. New diving equipment, such as remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs), has reduced the need for divers to work in hazardous environments. These vehicles can perform a wide range of tasks, including inspection, maintenance, and repair, without putting divers at risk.

Improved Safety Culture

A greater emphasis on safety culture has also contributed to improved offshore diving safety. Companies are now more focused on promoting a culture of safety, where employees are encouraged to report hazards, participate in safety training, and take ownership of their safety. This shift in culture has led to a reduction in accidents and injuries.

Expert Analysis of the Byford Dolphin Accident

Leading experts in offshore diving and safety have extensively analyzed the Byford Dolphin accident, providing valuable insights into the causes of the tragedy and the lessons learned. Their analysis highlights the importance of a multi-faceted approach to safety, encompassing technical design, human factors, and organizational culture.

Technical Design Considerations

Experts emphasize the need for robust technical design in diving systems to prevent accidents. This includes ensuring that equipment is properly maintained, that emergency shutdown systems are reliable, and that safety features are incorporated into the design from the outset. Redundancy is also crucial, with backup systems in place to mitigate the risk of equipment failure.

Human Factors Training

Human factors training is essential to address the potential for human error in diving operations. This training should focus on improving communication, coordination, and decision-making skills. It should also address the psychological challenges of working in a high-pressure environment and the importance of maintaining situational awareness.

Organizational Culture and Safety

Organizational culture plays a critical role in promoting safety. Companies must foster a culture where safety is valued, where employees are empowered to report hazards, and where continuous improvement is encouraged. This requires strong leadership, clear communication, and a commitment to providing the resources necessary to ensure safety.

Diving Operations Products and Safety Equipment

Several companies offer products and services designed to enhance the safety of diving operations. From advanced diving equipment to comprehensive safety training programs, these solutions aim to mitigate risks and protect divers in challenging underwater environments.

Leading Safety Equipment Providers

Companies like Kirby Morgan Dive Systems and Divex provide state-of-the-art diving helmets, suits, and communication systems. These products are designed to withstand extreme pressures and provide divers with the necessary protection and support to perform their tasks safely. Regular maintenance and inspection of this equipment are crucial to ensure its reliability.

Dive Support Vessels and Systems

Dive support vessels (DSVs) are equipped with advanced diving systems, including hyperbaric chambers, decompression facilities, and ROVs. These vessels provide a safe and controlled environment for diving operations, allowing divers to work at great depths for extended periods. Companies like TechnipFMC and Subsea 7 operate DSVs around the world.

Detailed Analysis of Diving Helmets and Their Safety Features

Diving helmets are a critical piece of safety equipment for divers, providing protection, communication, and a supply of breathable gas. Modern diving helmets incorporate numerous advanced features designed to enhance safety and performance.

Key Features of Modern Diving Helmets

1. **Durable Construction:** Modern diving helmets are constructed from high-strength materials, such as fiberglass and stainless steel, to withstand extreme pressures and impacts.

2. **Clear Communication Systems:** Integrated communication systems allow divers to communicate with surface personnel and other divers, ensuring clear and reliable communication at all times.

3. **Breathable Gas Supply:** Diving helmets provide a constant supply of breathable gas, typically a mixture of helium and oxygen, to support divers at great depths.

4. **Emergency Gas Supply:** In the event of a primary gas supply failure, diving helmets are equipped with an emergency gas supply that can provide divers with enough breathable gas to return to the surface.

5. **Underwater Lighting:** Integrated underwater lighting systems provide divers with visibility in dark or murky waters, enhancing safety and efficiency.

6. **Video Recording Capabilities:** Some diving helmets are equipped with video recording capabilities, allowing divers to document their work and provide valuable visual evidence for inspections and repairs.

7. **Comfort and Fit:** Modern diving helmets are designed for comfort and fit, with adjustable straps and padding to ensure a secure and comfortable fit for divers of all sizes.

Each of these features contributes to the overall safety and effectiveness of diving helmets, providing divers with the necessary protection and support to perform their tasks safely and efficiently.

Significant Advantages and Benefits of Enhanced Diving Safety Equipment

Investing in enhanced diving safety equipment offers numerous advantages and benefits for both divers and diving operations. These advantages include reduced risk of accidents, improved diver performance, and increased operational efficiency.

Reduced Risk of Accidents

Enhanced diving safety equipment significantly reduces the risk of accidents by providing divers with the necessary protection and support to perform their tasks safely. Features such as durable construction, clear communication systems, and emergency gas supplies can help prevent accidents and injuries.

Improved Diver Performance

Enhanced diving safety equipment can improve diver performance by providing divers with greater comfort, visibility, and communication capabilities. This allows divers to focus on their work without being distracted by discomfort or communication issues.

Increased Operational Efficiency

Enhanced diving safety equipment can increase operational efficiency by reducing downtime due to accidents or equipment failures. Reliable and well-maintained equipment ensures that diving operations can proceed smoothly and efficiently.

Comprehensive Review of the Kirby Morgan 97 Diving Helmet

The Kirby Morgan 97 diving helmet is a widely used and highly regarded piece of diving equipment, known for its durability, reliability, and advanced safety features. This comprehensive review provides an in-depth assessment of the helmet’s performance, usability, and overall value.

User Experience and Usability

The Kirby Morgan 97 diving helmet is designed for ease of use and comfort, even in challenging underwater environments. The helmet features adjustable straps and padding to ensure a secure and comfortable fit for divers of all sizes. The integrated communication system provides clear and reliable communication, allowing divers to communicate with surface personnel and other divers.

Performance and Effectiveness

The Kirby Morgan 97 diving helmet delivers exceptional performance in a wide range of diving conditions. The helmet’s durable construction protects divers from impacts and pressure, while the integrated gas supply system ensures a constant supply of breathable gas. The helmet’s underwater lighting system provides excellent visibility, even in dark or murky waters.

Pros

1. **Durability:** The Kirby Morgan 97 diving helmet is constructed from high-quality materials, ensuring long-lasting durability and reliability.

2. **Comfort:** The helmet is designed for comfort, with adjustable straps and padding to ensure a secure and comfortable fit.

3. **Communication:** The integrated communication system provides clear and reliable communication, enhancing safety and efficiency.

4. **Visibility:** The helmet’s underwater lighting system provides excellent visibility, even in dark or murky waters.

5. **Safety Features:** The helmet incorporates numerous safety features, including an emergency gas supply and a durable construction, to protect divers in challenging environments.

Cons/Limitations

1. **Cost:** The Kirby Morgan 97 diving helmet is a premium product and comes with a higher price tag than some other diving helmets.

2. **Weight:** The helmet is relatively heavy, which can be tiring for divers during extended dives.

3. **Maintenance:** The helmet requires regular maintenance and inspection to ensure its reliability and performance.

Ideal User Profile

The Kirby Morgan 97 diving helmet is best suited for professional divers who require a reliable and high-performance diving helmet for challenging underwater environments. It is particularly well-suited for commercial diving, salvage operations, and underwater construction.

Key Alternatives

1. **SuperLite 17B Diving Helmet:** The SuperLite 17B diving helmet is a popular alternative to the Kirby Morgan 97, offering similar features and performance at a slightly lower price point.

2. **Gorski Diving Helmet:** The Gorski diving helmet is a more affordable option, suitable for recreational diving and light commercial applications.

Expert Overall Verdict and Recommendation

The Kirby Morgan 97 diving helmet is an excellent choice for professional divers who require a reliable and high-performance diving helmet. While it comes with a higher price tag than some other options, its durability, comfort, and safety features make it a worthwhile investment.

Insightful Q&A Section

**Q1: What specific regulatory changes were implemented in Norway following the Byford Dolphin accident to prevent similar tragedies?**

**A:** Following the Byford Dolphin accident, Norway implemented stricter regulations regarding the design, operation, and maintenance of diving systems. These regulations included mandatory safety audits, enhanced training for diving personnel, and improved emergency response protocols. The Petroleum Safety Authority Norway (PSA) was also given greater authority to oversee and enforce safety standards in the offshore oil industry.

**Q2: How has the understanding of human factors in diving operations evolved since the Byford Dolphin accident?**

**A:** Since the Byford Dolphin accident, there has been a greater emphasis on understanding and addressing human factors in diving operations. This includes recognizing the impact of fatigue, stress, and communication breakdowns on diver performance. Training programs now incorporate human factors principles, and companies are implementing strategies to improve communication, coordination, and decision-making skills among diving teams.

**Q3: What role did the lack of independent verification of safety systems play in the Byford Dolphin accident, and how has this been addressed since then?**

**A:** The lack of independent verification of safety systems was a contributing factor in the Byford Dolphin accident. Since then, there has been a greater emphasis on independent verification and validation of safety systems to ensure that they meet the required standards. This includes third-party audits, inspections, and testing to identify potential weaknesses and ensure that systems are functioning correctly.

**Q4: What are the long-term psychological effects on divers who have experienced or witnessed diving accidents like the Byford Dolphin?**

**A:** Divers who have experienced or witnessed diving accidents like the Byford Dolphin may suffer from long-term psychological effects, including post-traumatic stress disorder (PTSD), anxiety, and depression. These effects can impact their ability to work and their overall quality of life. Companies are now more aware of the psychological needs of divers and are providing access to counseling and support services.

**Q5: How has the development of remotely operated vehicles (ROVs) impacted the need for human divers in offshore operations?**

**A:** The development of ROVs has significantly reduced the need for human divers in offshore operations. ROVs can perform a wide range of tasks, including inspection, maintenance, and repair, without putting divers at risk. This has led to a reduction in the number of divers employed in the offshore oil industry.

**Q6: What are the current best practices for emergency decompression procedures in saturation diving, and how do they differ from the procedures in place at the time of the Byford Dolphin accident?**

**A:** Current best practices for emergency decompression procedures in saturation diving involve a slow and controlled decompression process to minimize the risk of decompression sickness. This differs significantly from the procedures in place at the time of the Byford Dolphin accident, which were inadequate and contributed to the severity of the accident. Modern decompression procedures also incorporate advanced monitoring and support systems to ensure the safety of divers.

**Q7: How do modern diving suits and helmets protect divers from the extreme cold and pressure of deep-sea environments?**

**A:** Modern diving suits and helmets are designed to provide divers with thermal protection and pressure equalization in deep-sea environments. Diving suits are typically made from neoprene or other insulating materials to keep divers warm, while diving helmets provide a sealed environment that is pressurized to the same pressure as the surrounding water. This pressure equalization prevents divers from experiencing the effects of pressure on their bodies.

**Q8: What are the key advancements in underwater communication technology that have improved safety in diving operations?**

**A:** Key advancements in underwater communication technology include improved acoustic communication systems, digital signal processing, and wireless communication technologies. These advancements have improved the clarity, reliability, and range of underwater communication, allowing divers to communicate with surface personnel and other divers more effectively.

**Q9: How do modern diving support vessels (DSVs) enhance the safety and efficiency of diving operations?**

**A:** Modern DSVs are equipped with advanced diving systems, including hyperbaric chambers, decompression facilities, and ROVs. These vessels provide a safe and controlled environment for diving operations, allowing divers to work at great depths for extended periods. They also provide support services, such as medical care, emergency response, and logistical support.

**Q10: What are the ongoing research efforts aimed at further improving the safety and effectiveness of diving operations in the offshore oil industry?**

**A:** Ongoing research efforts are focused on developing new technologies, improving safety protocols, and enhancing the understanding of human factors in diving operations. This includes research into new diving equipment, advanced monitoring systems, and improved training programs. The goal is to continue to improve the safety and effectiveness of diving operations in the offshore oil industry.

Conclusion and Strategic Call to Action

The Byford Dolphin accident serves as a somber reminder of the inherent risks associated with deep-sea diving and the critical importance of prioritizing safety in all offshore operations. The lessons learned from this tragedy have led to significant advancements in safety regulations, equipment design, and training programs, ultimately contributing to a safer working environment for divers. While the offshore oil industry has made considerable progress in improving safety, it is essential to remain vigilant and continue to invest in research, technology, and training to prevent future accidents.

Looking ahead, the offshore oil industry must continue to embrace a culture of safety that values communication, collaboration, and continuous improvement. This requires strong leadership, clear communication, and a commitment to providing the resources necessary to ensure the safety of all personnel. By learning from the past and embracing a proactive approach to safety, the industry can minimize risks and protect the lives of those who work in this challenging environment.

We encourage you to share your thoughts and experiences regarding diving safety in the comments section below. If you are interested in learning more about advanced diving safety equipment or training programs, please explore our comprehensive guide to offshore diving safety or contact our experts for a consultation. Together, we can work towards a safer and more responsible offshore oil industry.