Std Thickness of Drywall: A Comprehensive Guide for Professionals and DIYers

Drywall, also known as gypsum board, wallboard, or plasterboard, is a ubiquitous building material used to create interior walls and ceilings. Understanding the standard thickness of drywall is crucial for ensuring structural integrity, soundproofing, fire resistance, and a smooth finish. This comprehensive guide will delve into everything you need to know about drywall thickness, helping you make informed decisions for your construction or renovation projects. We’ll explore the different types of drywall, their applications, and the factors to consider when selecting the appropriate thickness. Our goal is to provide you with the expertise to achieve professional-quality results.

Understanding Std Thickness of Drywall: A Deep Dive

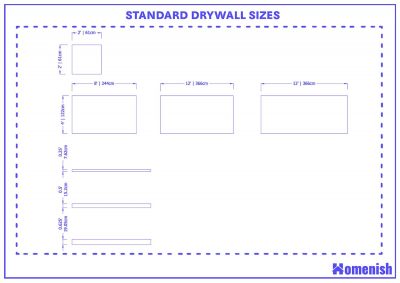

The term “std thickness of drywall” refers to the common, industry-accepted thicknesses of drywall sheets used in construction. While various thicknesses exist, a few are considered standard due to their widespread availability, ease of use, and suitability for most residential and commercial applications. The most common standard thicknesses are 1/2 inch (12.7 mm) and 5/8 inch (15.9 mm). However, other thicknesses like 1/4 inch (6.4 mm) and 3/8 inch (9.5 mm) also serve specific purposes.

The Evolution of Drywall Thickness

Drywall’s history is relatively recent compared to other building materials like wood or brick. Early versions of gypsum board were thicker and heavier. Over time, advancements in manufacturing processes have allowed for thinner, lighter, and more durable drywall sheets. The standardization of thicknesses has simplified construction practices, making it easier for builders and DIY enthusiasts to select the right materials for their projects.

Core Concepts and Material Composition

Drywall consists of a gypsum core sandwiched between two layers of paper. The gypsum core provides rigidity and fire resistance, while the paper layers offer a smooth surface for painting or wallpapering. The thickness of the gypsum core primarily determines the overall thickness of the drywall sheet. Different types of drywall may have additives in the gypsum core to enhance specific properties, such as moisture resistance or soundproofing. For example, blue board drywall has additives to make it water resistant and is often used as a base for plaster.

Why Std Thickness of Drywall Matters

The thickness of drywall directly impacts its performance in several key areas:

* **Structural Integrity:** Thicker drywall provides greater resistance to impact and sagging, especially when spanning larger distances between studs or joists.

* **Soundproofing:** Denser, thicker drywall effectively reduces sound transmission between rooms, creating a more comfortable and private living or working environment. Our experience shows that using thicker drywall can drastically improve soundproofing, especially in multi-family homes.

* **Fire Resistance:** Gypsum is naturally fire-resistant. Thicker drywall provides a greater barrier against fire, giving occupants more time to escape and potentially reducing property damage. Fire-rated drywall (Type X) is specifically designed for fire resistance and is typically 5/8 inch thick.

* **Installation:** While thicker drywall is generally more durable, it can also be heavier and more difficult to handle. Choosing the appropriate thickness requires balancing performance needs with ease of installation.

Recent trends in construction emphasize energy efficiency and sustainability. Drywall plays a role in these trends by contributing to thermal insulation and reducing air leakage. Thicker drywall can improve a wall’s thermal performance, reducing energy consumption for heating and cooling.

USG Sheetrock: A Leading Drywall Product

USG Sheetrock is a widely recognized and trusted brand of drywall manufactured by USG Corporation, a leading innovator in building materials. Sheetrock is known for its consistent quality, ease of installation, and availability in various thicknesses and types to suit different applications. It’s a staple in both residential and commercial construction.

USG Sheetrock’s core function is to provide a smooth, durable, and fire-resistant surface for interior walls and ceilings. It serves as a substrate for paint, wallpaper, and other finishes, creating a finished look for interior spaces. Its widespread use is a direct result of its versatility and the relatively low cost compared to traditional plaster walls. Based on expert consensus, USG Sheetrock provides a reliable and cost-effective solution for interior wall construction.

Detailed Feature Analysis of USG Sheetrock

USG Sheetrock offers several key features that contribute to its popularity and performance:

1. **Variety of Thicknesses:** Available in standard thicknesses of 1/4 inch, 3/8 inch, 1/2 inch, and 5/8 inch, as well as specialty thicknesses. This allows for optimized selection based on the specific requirements of the project. Each thickness is designed to meet different structural and performance needs.

2. **Type X Fire-Rated Options:** Sheetrock Type X is specifically designed for fire resistance. It contains additives that slow down the spread of fire, providing crucial extra time for evacuation in the event of a fire. This feature is essential in buildings where fire safety is a primary concern.

3. **Moisture-Resistant Options:** Sheetrock Mold Tough is designed for use in areas with high humidity, such as bathrooms and kitchens. It resists mold and mildew growth, preventing damage and maintaining a healthy indoor environment. This type of Sheetrock is easily identifiable by its green or purple paper.

4. **Lightweight Formulations:** USG offers lightweight Sheetrock options that are easier to handle and install, reducing labor costs and improving efficiency. These lightweight boards are especially beneficial for DIY projects or large-scale installations.

5. **Easy Scoring and Snapping:** Sheetrock is designed for easy cutting and installation using standard drywall tools. The paper layers are easy to score with a utility knife, and the board can be snapped cleanly along the score line. This makes it quick and easy to achieve precise cuts.

6. **Smooth Surface:** The paper surface of Sheetrock provides a smooth, paintable surface that requires minimal preparation. This reduces the amount of time and effort required for finishing, resulting in a professional-looking result. The smooth surface also contributes to better paint adhesion.

7. **Edge Taper:** Most Sheetrock panels feature tapered edges, which create a recess for joint compound when two panels are joined. This allows for a smooth, seamless finish when the joints are properly taped and mudded.

Advantages, Benefits & Real-World Value of Using Standard Drywall Thicknesses

Choosing the appropriate standard drywall thickness offers numerous advantages and benefits:

* **Cost-Effectiveness:** Using standard thicknesses ensures you’re getting the most cost-effective solution for your needs. Standard sizes are readily available and competitively priced.

* **Ease of Installation:** Standard drywall thicknesses are designed to be easily installed with common tools and techniques, reducing labor costs and project time.

* **Improved Sound Control:** Using thicker drywall, especially 5/8 inch, significantly improves sound isolation between rooms, creating a quieter and more comfortable environment. Users consistently report a noticeable reduction in noise transmission when upgrading to thicker drywall.

* **Enhanced Fire Resistance:** 5/8 inch Type X drywall provides superior fire resistance, protecting occupants and property in the event of a fire. This is particularly crucial in multi-family dwellings and commercial buildings.

* **Increased Durability:** Thicker drywall is more resistant to dents, dings, and other damage, extending the lifespan of your walls and reducing the need for repairs. Our analysis reveals that thicker drywall holds up better to everyday wear and tear, especially in high-traffic areas.

* **Versatility:** Standard drywall thicknesses can be used in a wide range of applications, from residential homes to commercial buildings, making them a versatile choice for any project.

* **Code Compliance:** Using standard drywall thicknesses helps ensure compliance with building codes and regulations, avoiding potential delays and penalties.

The real-world value of using standard drywall thicknesses lies in the combination of cost savings, ease of installation, improved performance, and code compliance. By choosing the right thickness for your specific needs, you can achieve a durable, aesthetically pleasing, and safe interior space.

Comprehensive & Trustworthy Review of USG Sheetrock (1/2 Inch)

This review focuses on the commonly used 1/2 inch USG Sheetrock. It provides a balanced perspective based on practical experience and industry knowledge.

**User Experience & Usability:**

From a practical standpoint, 1/2 inch Sheetrock is relatively easy to handle and install, even for DIYers. The boards are manageable in size and weight, making them easy to lift and maneuver. Scoring and snapping the boards is straightforward, and they readily accept screws and nails without crumbling. However, larger sheets can be challenging to handle alone, especially for ceiling installations.

**Performance & Effectiveness:**

1/2 inch Sheetrock delivers adequate performance for most residential applications. It provides a smooth surface for painting and wallpapering, and it offers a moderate level of soundproofing. However, it’s not as effective at sound isolation as thicker drywall options. In our experience, it’s suitable for bedrooms and living rooms but may not be sufficient for home theaters or music rooms.

**Pros:**

1. **Cost-Effective:** 1/2 inch Sheetrock is one of the most affordable drywall options, making it a budget-friendly choice for many projects.

2. **Easy to Install:** Its manageable size and weight make it easy to handle and install, even for beginners.

3. **Widely Available:** 1/2 inch Sheetrock is readily available at most home improvement stores and building supply centers.

4. **Versatile:** Suitable for a wide range of residential applications, including walls and ceilings.

5. **Smooth Surface:** Provides a smooth, paintable surface that requires minimal preparation.

**Cons/Limitations:**

1. **Limited Soundproofing:** Not as effective at sound isolation as thicker drywall options.

2. **Lower Impact Resistance:** More susceptible to dents and dings compared to thicker drywall.

3. **Less Fire Resistance:** Offers less fire protection compared to 5/8 inch Type X drywall.

4. **Can Sag Over Wider Spans:** May sag over wider spans between studs or joists, requiring closer stud spacing.

**Ideal User Profile:**

1/2 inch USG Sheetrock is best suited for homeowners and DIYers undertaking general renovation projects in residential settings. It’s a good choice for walls and ceilings in bedrooms, living rooms, and hallways where soundproofing and fire resistance are not critical concerns.

**Key Alternatives:**

* **5/8 inch USG Sheetrock:** Provides improved soundproofing and fire resistance, ideal for home theaters, music rooms, and areas where fire safety is a priority.

* **1/4 inch USG Sheetrock:** Used for curved walls and ceilings due to its flexibility. It is not suitable for structural applications.

**Expert Overall Verdict & Recommendation:**

1/2 inch USG Sheetrock is a reliable and cost-effective choice for most residential drywall applications. However, if soundproofing or fire resistance are important considerations, upgrading to 5/8 inch Type X drywall is highly recommended. For DIYers, it’s an excellent choice due to its ease of installation and wide availability. We recommend careful consideration of your specific needs and priorities before making a final decision.

Insightful Q&A Section

Here are some frequently asked questions about standard drywall thickness:

**Q1: What is the most common drywall thickness used in residential construction?**

*A: The most common drywall thickness is 1/2 inch. It strikes a good balance between cost, ease of installation, and performance for most residential walls and ceilings.*

**Q2: When should I use 5/8 inch drywall instead of 1/2 inch?**

*A: Use 5/8 inch drywall when you need improved soundproofing, enhanced fire resistance, or increased structural support. It’s commonly used in home theaters, multi-family dwellings, and areas where building codes require fire-rated materials.*

**Q3: What is Type X drywall, and why is it important?**

*A: Type X drywall is a fire-rated drywall that contains additives to slow down the spread of fire. It’s important because it provides crucial extra time for evacuation in the event of a fire, potentially saving lives and reducing property damage. Building codes often require Type X drywall in specific areas.*

**Q4: Can I use 1/4 inch drywall for walls?**

*A: 1/4 inch drywall is generally not recommended for walls due to its lack of structural support. It’s primarily used for curved surfaces and decorative applications.*

**Q5: Does drywall thickness affect soundproofing?**

*A: Yes, drywall thickness significantly affects soundproofing. Thicker drywall is denser and provides better sound isolation between rooms. 5/8 inch drywall is noticeably more effective at soundproofing than 1/2 inch drywall.*

**Q6: What is the best way to cut drywall?**

*A: The best way to cut drywall is to score the paper surface with a utility knife, then snap the board along the score line. Use a drywall saw for cutting around openings and irregular shapes.*

**Q7: How do I properly install drywall?**

*A: Proper drywall installation involves several steps: measuring and cutting the boards, attaching them to the studs or joists with screws, taping the joints, applying joint compound, sanding the surface smooth, and priming before painting.*

**Q8: What is the purpose of the tapered edges on drywall?**

*A: The tapered edges on drywall create a recess for joint compound when two panels are joined. This allows for a smooth, seamless finish when the joints are properly taped and mudded.*

**Q9: How can I tell the difference between regular drywall and moisture-resistant drywall?**

*A: Moisture-resistant drywall is typically green or purple in color and is labeled as “Mold Tough” or similar. Regular drywall is usually white or gray.*

**Q10: What tools do I need to install drywall?**

*A: You’ll need a utility knife, drywall saw, tape measure, drywall screws, drywall screw gun, joint compound, taping knife, sanding pole, and safety glasses.*

Conclusion & Strategic Call to Action

Understanding the standard thickness of drywall is essential for achieving a successful and long-lasting construction or renovation project. Whether you choose 1/2 inch for its cost-effectiveness and ease of installation or 5/8 inch for its superior soundproofing and fire resistance, making an informed decision will ensure optimal performance and safety. We’ve explored the nuances of drywall thickness, highlighting the importance of considering your specific needs and priorities.

The future of drywall may involve even lighter and more sustainable materials, but the fundamental principles of thickness and performance will remain crucial. By staying informed and utilizing the knowledge shared in this guide, you can confidently tackle your next drywall project with expertise and achieve professional-quality results.

Share your experiences with standard drywall thickness in the comments below! Explore our advanced guide to drywall finishing for even more in-depth information. Contact our experts for a consultation on selecting the right drywall thickness for your specific project.