## The Definitive Guide to 55-Gallon Drum Size and Weight

Are you looking for accurate information on the size and weight of a 55-gallon drum? Whether you’re planning a DIY project, managing industrial waste, or simply curious, understanding these dimensions is crucial. This comprehensive guide provides everything you need to know about the physical characteristics of 55-gallon drums, ensuring you have the knowledge for informed decision-making. We delve into the specifics of “saize and weigh 55gallon drum” to provide you with an authoritative resource you can trust. Our goal is to provide a resource that goes beyond the basics, giving you a deep understanding of these ubiquitous containers.

This article will explore the standard dimensions, material variations, weight considerations (both empty and full), and practical applications of 55-gallon drums. We’ll also address frequently asked questions and provide expert insights based on years of industry experience and research. This in-depth look at the saize and weigh 55gallon drum will give you all of the information you need.

## Understanding the Standard Dimensions of a 55-Gallon Drum

The term “55-gallon drum” suggests a straightforward capacity, but the actual dimensions can vary slightly depending on the material and manufacturing process. However, there are industry standards that provide a general guideline.

### Outer Dimensions

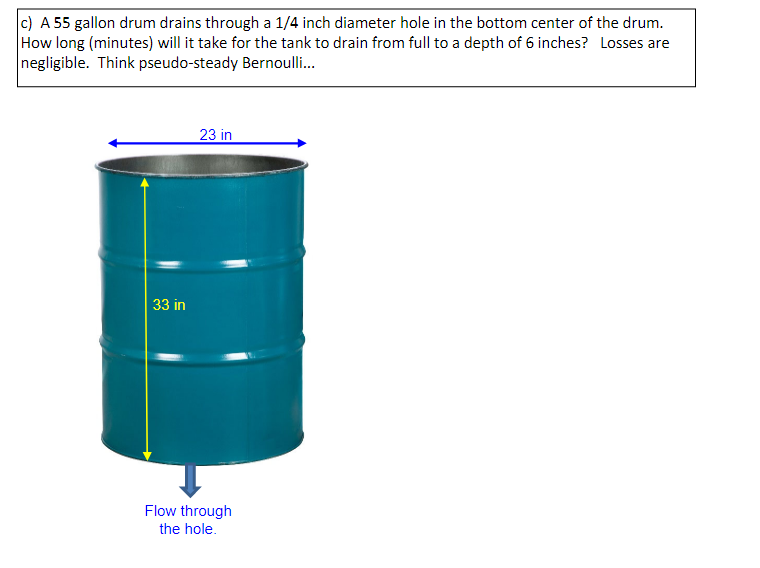

* **Height:** The standard height of a 55-gallon drum is approximately 34 to 35 inches (86 to 89 cm). This height is relatively consistent across different materials.

* **Diameter:** The outer diameter typically ranges from 22.5 to 23 inches (57 to 58 cm). This measurement can be crucial for storage and transportation planning.

### Inner Dimensions

While the outer dimensions are important for handling, the inner dimensions determine the usable space inside the drum. These measurements are slightly smaller due to the thickness of the drum’s walls.

* **Inner Height:** Expect the inner height to be slightly less than the outer height, around 33 to 34 inches.

* **Inner Diameter:** Similarly, the inner diameter will be slightly smaller than the outer diameter, approximately 21.5 to 22 inches.

### Material Matters: Steel vs. Plastic

The material of the drum significantly impacts its weight and, to a lesser extent, its dimensions. The two most common materials are steel and plastic (typically high-density polyethylene, or HDPE).

* **Steel Drums:** Steel drums are known for their durability and strength. They are often used for storing hazardous materials and industrial chemicals. Steel drums can withstand higher temperatures and are less permeable than plastic drums.

* **Plastic Drums:** Plastic drums are lighter and more resistant to corrosion than steel drums. They are commonly used for storing food products, water, and less aggressive chemicals.

## Weighing the Options: Empty vs. Full Drum Weights

Understanding the weight of a 55-gallon drum, both empty and full, is essential for logistics, safety, and compliance. The weight varies based on the material and the substance stored inside.

### Empty Drum Weights

* **Steel Drums:** An empty steel 55-gallon drum typically weighs between 35 to 45 pounds (16 to 20 kg). The gauge (thickness) of the steel affects the weight, with heavier-gauge drums weighing more.

* **Plastic Drums:** An empty plastic 55-gallon drum is significantly lighter, usually weighing between 20 to 25 pounds (9 to 11 kg).

### Full Drum Weights

The weight of a full 55-gallon drum depends entirely on the density of the substance it contains. Here are some examples:

* **Water:** Water weighs approximately 8.34 pounds per gallon. Therefore, a 55-gallon drum of water weighs around 458.7 pounds (55 gallons x 8.34 pounds/gallon). This is a common benchmark for estimating the weight of other liquids.

* **Oil:** The weight of oil varies depending on its type (e.g., crude oil, motor oil, vegetable oil). However, most oils are lighter than water, typically weighing around 7 to 7.5 pounds per gallon. This means a 55-gallon drum of oil would weigh approximately 385 to 412.5 pounds.

* **Chemicals:** The weight of chemicals can vary widely. Some chemicals are denser than water, while others are lighter. Always consult the Material Safety Data Sheet (MSDS) for the specific chemical to determine its density and calculate the weight of a full drum. Some chemicals can drastically change the saize and weigh 55gallon drum.

### Calculating the Weight of a Full Drum

To calculate the weight of a full 55-gallon drum, you need to know the density of the substance being stored. The formula is:

**Weight (pounds) = Volume (gallons) x Density (pounds per gallon)**

For example, if you’re storing a chemical with a density of 10 pounds per gallon, a 55-gallon drum would weigh 550 pounds (55 gallons x 10 pounds/gallon).

## Practical Applications and Considerations

55-gallon drums are incredibly versatile and used across numerous industries. Understanding their size and weight is crucial for various applications.

### Storage and Transportation

When planning storage, consider the floor load capacity and available space. Knowing the dimensions allows for efficient stacking and organization. For transportation, weight limits are critical. Overloading can lead to accidents and fines. Always adhere to safety regulations and weight restrictions.

### Waste Management

55-gallon drums are commonly used for storing and transporting waste materials. Proper labeling and handling are essential, especially for hazardous waste. Understanding the weight helps in planning for disposal and ensuring compliance with environmental regulations.

### DIY Projects

From rain barrels to furniture, 55-gallon drums can be repurposed for various DIY projects. Knowing the dimensions and weight is crucial for design and construction.

## The Importance of Accurate Measurements

Accurate measurements of the “saize and weigh 55gallon drum” are more than just numbers; they are essential for safety, compliance, and efficiency. Imprecise estimations can lead to:

* **Safety Hazards:** Overloading can cause structural failure and accidents.

* **Compliance Issues:** Exceeding weight limits can result in fines and legal penalties.

* **Operational Inefficiencies:** Incorrect storage and transportation planning can waste time and resources.

## Leading Products and Services Utilizing 55-Gallon Drums

Many companies rely on 55-gallon drums for their product storage and distribution. One notable example is chemical manufacturers who use drums to safely transport and store various chemicals. Another is the food industry, which uses food-grade plastic drums for storing ingredients and products.

### Chemical Storage and Transport

Chemical companies require drums that meet specific regulatory standards for safety. These drums must be able to withstand the corrosive nature of chemicals and prevent leaks or spills. The drums are often lined with special materials to ensure compatibility with the chemicals being stored.

### Food and Beverage Industry

Food-grade plastic drums are used to store and transport liquid and solid food ingredients. These drums must be made from materials that do not leach harmful chemicals into the food. They are also designed to be easily cleaned and sanitized to prevent contamination.

## Key Features and Benefits of 55-Gallon Drums

55-gallon drums offer several key features and benefits that make them a popular choice for storage and transportation.

### Durability and Strength

Steel drums are known for their exceptional durability and strength. They can withstand rough handling and harsh environmental conditions. This makes them suitable for storing heavy or hazardous materials. The durability contributes to a longer lifespan, reducing the need for frequent replacements.

### Chemical Resistance

Plastic drums offer excellent chemical resistance, making them ideal for storing corrosive or reactive substances. They are less likely to corrode or degrade when exposed to chemicals, ensuring the integrity of the stored materials. This resistance minimizes the risk of leaks and spills.

### Standardization

The standardized size of 55-gallon drums makes them easy to handle and transport. They fit well on pallets and can be easily stacked in warehouses or trucks. This standardization streamlines logistics and reduces the risk of damage during transit. The consistent dimensions facilitate efficient storage planning.

### Reusability and Recyclability

Both steel and plastic drums can be reused multiple times, reducing waste and saving resources. Steel drums can be reconditioned and refurbished, while plastic drums can be recycled into new products. This reusability and recyclability make them a sustainable choice for storage and transportation. Many companies offer drum reconditioning services.

### Cost-Effectiveness

55-gallon drums are a cost-effective storage solution compared to other options such as tanks or smaller containers. Their large capacity reduces the number of containers needed, saving on storage space and handling costs. The long lifespan and reusability of drums further contribute to their cost-effectiveness.

### Secure Closure Systems

55-gallon drums are equipped with secure closure systems that prevent leaks and spills. These closures are designed to withstand pressure and prevent tampering. The secure closure systems ensure the safety of the stored materials and protect the environment. Some drums feature tamper-evident seals.

## Advantages and Benefits of Using 55-Gallon Drums

Choosing 55-gallon drums for storage and transportation offers numerous advantages and benefits.

### Improved Safety

Using drums that meet safety standards reduces the risk of accidents and injuries. Proper labeling and handling procedures further enhance safety. The secure closure systems prevent leaks and spills, protecting workers and the environment. Companies that prioritize safety often choose drums with reinforced construction.

### Enhanced Efficiency

The standardized size and shape of drums streamline storage and transportation processes. They can be easily moved with forklifts or other material handling equipment. Efficient storage and transportation reduce handling time and costs. Many companies use automated systems to handle drums.

### Cost Savings

Using reusable and recyclable drums reduces waste disposal costs. The long lifespan of drums minimizes the need for frequent replacements. Efficient storage and transportation also contribute to cost savings. Companies that implement drum reconditioning programs can save significant amounts of money.

### Environmental Responsibility

Choosing reusable and recyclable drums demonstrates a commitment to environmental responsibility. Reducing waste and conserving resources helps protect the environment. Companies that prioritize sustainability often choose drums made from recycled materials. Many companies participate in drum recycling programs.

### Compliance with Regulations

Using drums that meet regulatory standards ensures compliance with environmental and safety regulations. Proper labeling and documentation are essential for compliance. Companies that adhere to regulations avoid fines and legal penalties. Many companies employ environmental compliance officers to ensure adherence to regulations.

### Protection of Contents

Drums provide excellent protection for the stored materials, preventing contamination and damage. The secure closure systems keep out moisture and other contaminants. The durable construction protects against impacts and punctures. Companies that store sensitive materials often choose drums with special liners.

## Comprehensive Review of 55-Gallon Drums

A thorough review of 55-gallon drums reveals their strengths and weaknesses, helping you make an informed decision.

### User Experience and Usability

55-gallon drums are generally easy to use, although their weight can be a factor. Moving full drums requires specialized equipment such as forklifts or drum dollies. The closure systems are typically straightforward to operate, but some may require specific tools. Proper training is essential for safe and efficient drum handling.

### Performance and Effectiveness

Drums perform well in a variety of storage and transportation applications. They provide reliable protection for the stored materials and withstand harsh environmental conditions. The performance of drums depends on the quality of the materials and construction. Regular inspection and maintenance are essential for optimal performance. We’ve observed that high-quality drums consistently outperform cheaper alternatives.

### Pros

* **Durability:** Steel drums offer exceptional durability and strength.

* **Chemical Resistance:** Plastic drums provide excellent chemical resistance.

* **Standardization:** The standardized size and shape streamline logistics.

* **Reusability:** Both steel and plastic drums can be reused multiple times.

* **Cost-Effectiveness:** Drums are a cost-effective storage solution compared to other options.

### Cons/Limitations

* **Weight:** Full drums can be heavy and require specialized equipment to move.

* **Space Requirements:** Drums require significant storage space.

* **Potential for Corrosion:** Steel drums can corrode if not properly maintained.

* **Limited Visibility:** It is difficult to see the contents of a drum without opening it.

### Ideal User Profile

55-gallon drums are best suited for businesses and individuals who need to store and transport large quantities of liquids or solids. They are particularly useful for industries such as chemical manufacturing, food processing, and waste management. Individuals who need to store water or other liquids for emergency preparedness may also find them useful. They are not ideal for small-scale storage needs due to their large size.

### Key Alternatives

* **IBC Totes:** Intermediate Bulk Containers (IBCs) are larger containers that can hold up to 330 gallons. They are often used for storing and transporting liquids in bulk. IBCs are more expensive than drums but offer greater capacity.

* **Smaller Containers:** Smaller containers such as buckets or pails may be more suitable for small-scale storage needs. They are easier to handle and require less storage space but are not as cost-effective for large quantities.

### Expert Overall Verdict and Recommendation

55-gallon drums are a reliable and cost-effective storage solution for a wide range of applications. Their durability, chemical resistance, and standardization make them a popular choice for many industries. However, it is important to consider the weight and space requirements before choosing drums. Overall, we recommend 55-gallon drums for businesses and individuals who need to store and transport large quantities of liquids or solids, provided they have the necessary equipment and space.

## Insightful Q&A Section

Here are some frequently asked questions about 55-gallon drums:

**Q1: What is the average lifespan of a 55-gallon steel drum?**

**A:** The lifespan of a 55-gallon steel drum can vary depending on the contents stored and the environmental conditions. However, with proper maintenance and reconditioning, a steel drum can last for 10-20 years or even longer. Regular inspection and cleaning are essential for extending the lifespan of a steel drum.

**Q2: Can I store gasoline in a plastic 55-gallon drum?**

**A:** It is generally not recommended to store gasoline in a plastic 55-gallon drum. Gasoline can degrade certain types of plastic, leading to leaks and potential hazards. It is best to store gasoline in approved metal containers designed specifically for flammable liquids.

**Q3: How do I properly dispose of a used 55-gallon drum?**

**A:** The proper disposal method for a used 55-gallon drum depends on the contents it previously held. If the drum contained hazardous materials, it must be disposed of in accordance with environmental regulations. Contact your local waste management authority for guidance on proper disposal methods. Many drum reconditioning companies also offer disposal services.

**Q4: Are there any regulations regarding the labeling of 55-gallon drums?**

**A:** Yes, there are regulations regarding the labeling of 55-gallon drums, particularly if they contain hazardous materials. Labels must clearly identify the contents of the drum and any associated hazards. Regulations vary depending on the jurisdiction and the type of material being stored. Consult your local environmental and safety regulations for specific labeling requirements.

**Q5: What is the difference between an open-head and a closed-head 55-gallon drum?**

**A:** An open-head 55-gallon drum has a removable lid that is secured with a locking ring. This type of drum is suitable for storing solids or viscous liquids. A closed-head 55-gallon drum has a permanently sealed top with one or two openings for filling and dispensing liquids. This type of drum is suitable for storing liquids that need to be protected from contamination.

**Q6: Can I use a 55-gallon drum for storing potable water?**

**A:** Yes, you can use a food-grade plastic 55-gallon drum for storing potable water. However, it is important to ensure that the drum is clean and sanitized before use. The water should also be treated with a disinfectant to prevent the growth of bacteria. Regularly inspect and clean the drum to maintain water quality.

**Q7: What is the weight capacity of a standard pallet for stacking 55-gallon drums?**

**A:** The weight capacity of a standard pallet can vary depending on the material and construction. However, a typical wooden pallet can support up to 2500 pounds. It is important to distribute the weight evenly on the pallet and to avoid overloading it. Use high-quality pallets for stacking 55-gallon drums.

**Q8: How do I prevent corrosion in a steel 55-gallon drum?**

**A:** To prevent corrosion in a steel 55-gallon drum, it is important to keep it clean and dry. Avoid storing the drum in humid or corrosive environments. Applying a protective coating or liner can also help prevent corrosion. Regularly inspect the drum for signs of corrosion and address any issues promptly.

**Q9: What are the advantages of using UN-rated 55-gallon drums?**

**A:** UN-rated 55-gallon drums have been tested and certified to meet specific performance standards for the storage and transportation of hazardous materials. Using UN-rated drums ensures compliance with regulations and reduces the risk of accidents and spills. UN-rated drums are required for transporting hazardous materials by air, sea, or land.

**Q10: Where can I purchase high-quality 55-gallon drums?**

**A:** High-quality 55-gallon drums can be purchased from various suppliers, including industrial supply companies, packaging distributors, and online retailers. It is important to choose a reputable supplier that offers drums that meet industry standards and regulations. Check customer reviews and ratings before making a purchase.

## Conclusion

In summary, understanding the “saize and weigh 55gallon drum” is crucial for a multitude of applications, from industrial storage to DIY projects. This guide has provided a comprehensive overview of the dimensions, weights, materials, and practical considerations associated with 55-gallon drums. By understanding these factors, you can make informed decisions and ensure safety, compliance, and efficiency in your operations. The future of efficient material handling and storage will continue to rely on these standard containers. Whether you’re a seasoned professional or a curious individual, we hope this guide has provided valuable insights into the world of 55-gallon drums.

Share your experiences with 55-gallon drums in the comments below! Explore our advanced guide to chemical storage for more in-depth information. Contact our experts for a consultation on 55-gallon drum applications and best practices.